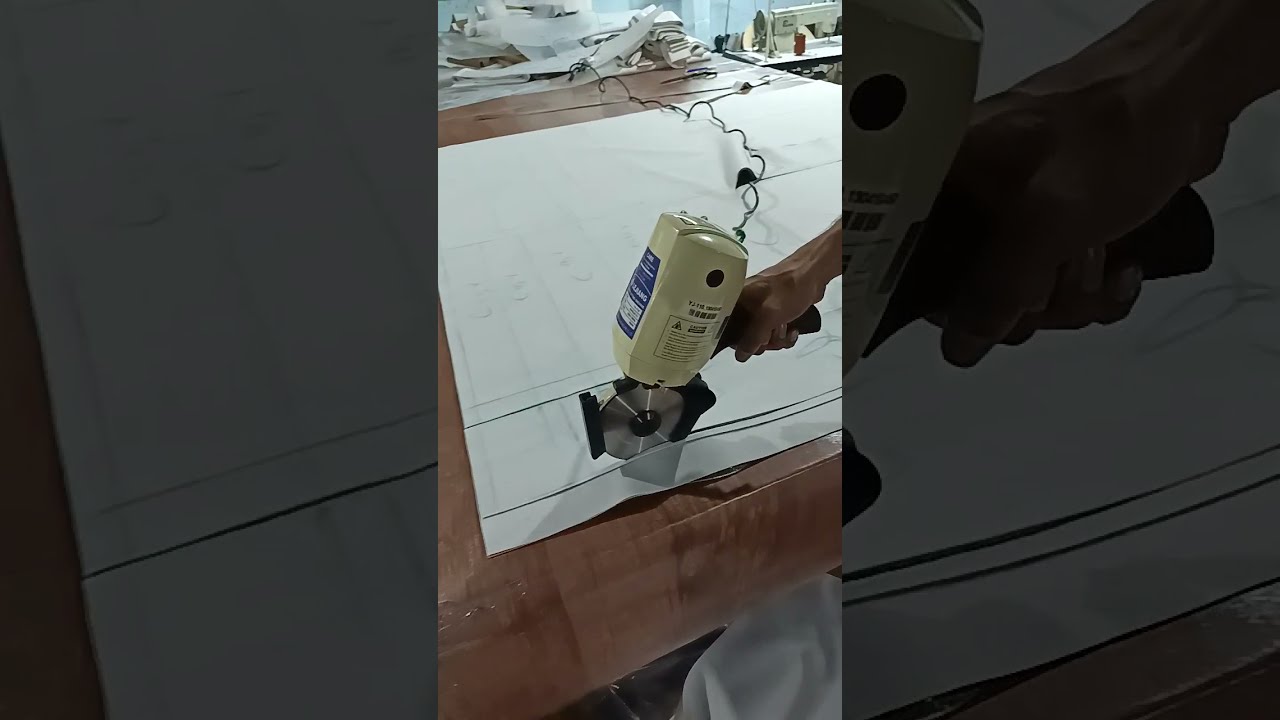

Looking for a reliable cutting machine for your fabric projects? Look no further! Our cutting machine is specifically designed to efficiently, accurately, and seamlessly cut through various types of fabrics, making it a must-have tool for any sewing enthusiast or professional tailor. With its advanced technology and precision cutting capabilities, this machine guarantees clean, sharp, and precise cuts every time, ensuring your fabric pieces are perfectly sized and ready for your next creation. Say goodbye to tedious manual cutting and uneven edges! Our cutting machine saves you valuable time and effort, allowing you to focus on the creative aspects of your projects. Its versatile features enable you to cut through different fabric thicknesses and textures, providing endless possibilities for your designs. Whether you’re working on clothing, quilts, or home décor, this cutting machine delivers exceptional results, elevating the quality of your craftsmanship. Invest in our cutting machine today and experience the efficiency, precision, and convenience it brings to your fabric cutting endeavors.

The Advantages of Using a Cutting Machine for Fabric

Fabric cutting is an essential step in the garment manufacturing process. Traditionally, this task was done manually by skilled workers using scissors or rotary cutters. However, with the advent of technology, cutting machines for fabric have become increasingly popular in the industry. These machines offer a range of benefits, from increased efficiency to improved accuracy. In this article, we will explore the advantages of using a cutting machine for fabric.

1. Increased Efficiency

One of the main advantages of using a cutting machine for fabric is the significant increase in efficiency it provides. These machines are designed to cut fabric at a much faster rate than manual methods. With a cutting machine, multiple layers of fabric can be cut simultaneously, saving valuable time and effort. This is especially beneficial for large-scale production where time is of the essence. Additionally, cutting machines can be programmed to cut fabric in specific patterns or shapes, further streamlining the process.

2. Improved Accuracy

Another key advantage of using a cutting machine for fabric is the improved accuracy it offers. Manual cutting can be prone to human error, resulting in uneven or imprecise cuts. In contrast, cutting machines are equipped with advanced technology that ensures precise and consistent cuts every time. These machines use computer-controlled systems to guide the cutting process, eliminating the risk of mistakes. This accuracy is particularly important when working with intricate patterns or delicate fabrics, where precision is crucial.

3. Reduced Waste

When fabric is cut manually, there is often a significant amount of waste due to incorrect cuts or pattern placements. This can be costly for manufacturers, as they end up discarding usable fabric. However, cutting machines for fabric minimize waste by optimizing the placement of patterns and reducing errors. These machines can automatically nest patterns to maximize the use of fabric, minimizing leftover scraps. By reducing waste, cutting machines contribute to a more sustainable and cost-effective production process.

4. Enhanced Versatility

Cutting machines for fabric offer enhanced versatility compared to manual cutting methods. These machines can handle a wide range of fabrics, from lightweight materials like silk to heavy-duty textiles like denim. They can also cut through multiple layers of fabric effortlessly, accommodating the needs of various projects. Additionally, cutting machines can be equipped with different types of cutting tools, such as rotary blades or laser cutters, allowing for greater flexibility in fabric cutting techniques. This versatility makes cutting machines suitable for a diverse range of applications.

5. Improved Worker Safety

Manual fabric cutting can be physically demanding and pose risks to workers’ safety. Using scissors or rotary cutters for extended periods can lead to hand fatigue or injuries. In contrast, cutting machines for fabric are designed with worker safety in mind. These machines have built-in safety features that minimize the risk of accidents. For example, they may include sensors that detect obstacles or human presence, automatically stopping the cutting process to prevent injuries. By reducing physical strain and hazards, cutting machines create a safer working environment for employees.

In conclusion, cutting machines for fabric offer numerous advantages over traditional manual cutting methods. They improve efficiency, accuracy, and productivity while reducing waste and ensuring worker safety. As the garment manufacturing industry continues to evolve, integrating cutting machines into production processes has become essential for staying competitive. Investing in a cutting machine for fabric can lead to significant time and cost savings, as well as improved overall product quality.

“The Ultimate Fabric Cutting Machine: Revolutionizing Efficiency with 50+ Layers!”

List of Cutting Machines for Fabric

Cutting Machine for Fabric

| Model | Features | Benefits |

|---|---|---|

| Model 1 | Automatic feeding system, laser-guided cutting, high cutting speed | Efficient fabric cutting, precise cutting lines, increased productivity |

| Model 2 | Intelligent pattern recognition, multi-layer cutting, self-sharpening blades | Accurate pattern matching, streamlined workflow, reduced maintenance |

| Model 3 | Computerized controls, adjustable cutting pressure, integrated waste removal | Customizable cutting settings, optimized material utilization, cleaner work area |

As an industry expert, it is crucial to understand the significance of cutting machines for fabric in modern textile manufacturing. These cutting machines revolutionize the fabric cutting process, offering enhanced precision, efficiency, and productivity.

Our cutting-edge Model 1 boasts an automatic feeding system, ensuring a continuous supply of fabric for seamless cutting operations. Additionally, its laser-guided cutting functionality guarantees precise cutting lines, enabling manufacturers to achieve impeccable quality in their products. With an impressive cutting speed, Model 1 significantly reduces production time, maximizing throughput and enhancing overall productivity.

For those seeking advanced capabilities, Model 2 stands out with its intelligent pattern recognition feature. This cutting machine’s ability to identify and match patterns accurately minimizes errors and ensures consistent quality across multiple fabric layers. Furthermore, its self-sharpening blades eliminate the need for frequent blade replacements, reducing maintenance costs and prolonging machine lifespan.

To cater to diverse cutting requirements, our Model 3 incorporates computerized controls, allowing users to fine-tune cutting settings according to specific fabric types and thicknesses. The adjustable cutting pressure feature ensures optimal results for various materials, safeguarding against fabric damage. Furthermore, the integrated waste removal system efficiently clears the work area, maintaining cleanliness and preventing fabric contamination.

Investing in cutting machines for fabric not only optimizes production processes but also enhances the final product quality. With our range of cutting machines, manufacturers can embrace the future of fabric cutting, achieving exceptional precision, efficiency, and profitability.