Precision metal fabricators are skilled craftsmen who specialize in transforming raw metal materials into intricate and high-quality products. With their expert knowledge and attention to detail, they are able to create bespoke metal components that meet the exact specifications and requirements of their clients. Utilizing cutting-edge technology and state-of-the-art equipment, precision metal fabricators are capable of producing a wide range of metal products, including precision parts for machinery, architectural structures, automotive components, and more. Their meticulous approach ensures that every piece they create is of the highest standard, guaranteeing durability, functionality, and aesthetic appeal. Whether it’s a custom-designed metal prototype or a large-scale production run, precision metal fabricators have the expertise and experience to deliver exceptional results. By partnering with these skilled professionals, businesses can benefit from their ability to bring ideas to life and create metal products that are not only reliable but also visually striking. The dedication and craftsmanship of precision metal fabricators make them an invaluable asset in industries where precision and quality are paramount.

Precision Metal Fabricators: Crafting Perfection in Metal

When it comes to creating intricate metal components with utmost precision, precision metal fabricators are the experts you need. These highly skilled professionals specialize in the art of shaping and manipulating metal into complex designs and structures. From small-scale decorative pieces to large industrial components, precision metal fabricators can bring your ideas to life with their exceptional craftsmanship.

The Role of Precision Metal Fabricators

Precision metal fabricators play a vital role in various industries, including aerospace, automotive, electronics, and construction. Their expertise lies in transforming raw metal materials into functional and aesthetically pleasing products. They work with a range of metals, such as stainless steel, aluminum, brass, and copper, utilizing advanced techniques and state-of-the-art equipment.

The Process of Precision Metal Fabrication

Precision metal fabrication involves a meticulous step-by-step process to ensure the highest level of accuracy and quality. Here’s an overview of the typical process followed by metal fabricators:

1. Design and Planning

The initial stage involves collaborating with clients to understand their specific requirements and design preferences. Design and planning are crucial to ensure the final product meets the desired specifications. Fabricators use computer-aided design (CAD) software to create detailed digital models of the product.

2. Material Selection

Choosing the right metal for the project is essential. Each metal has its unique properties and characteristics, which can affect the final product’s performance and durability. Material selection is based on factors such as strength, corrosion resistance, conductivity, and appearance.

3. Cutting and Shaping

Once the design and material are finalized, the next step is to cut and shape the metal. Fabricators utilize various cutting techniques such as laser cutting, plasma cutting, waterjet cutting, or shearing to achieve precise shapes and sizes.

4. Forming and Bending

After cutting, the metal is formed and bent into the desired shape. This process involves using specialized bending machines, press brakes, or rolling equipment to achieve the desired curvature and angles.

5. Joining and Assembly

Joining and assembly involve welding, fastening, or soldering different metal components together. Fabricators use advanced techniques and equipment to ensure strong and secure connections. Precision is crucial to maintain the structural integrity and functionality of the final product.

The Advantages of Precision Metal Fabrication

Precision metal fabrication offers several advantages over other manufacturing methods:

1. Customization

Precision metal fabricators can accommodate unique design ideas and create one-of-a-kind products tailored to individual requirements. The ability to customize metal components allows for greater flexibility and creativity in various industries.

2. Durability and Strength

Products created through precision metal fabrication are known for their exceptional durability and strength. The precise cutting, shaping, and joining techniques ensure that the final product can withstand extreme conditions, heavy loads, and rigorous use.

3. Cost-Effectiveness

While precision metal fabrication may involve initial setup costs, it offers long-term cost savings. The durability and low maintenance requirements of metal components reduce the need for frequent replacements, resulting in overall cost-effectiveness.

4. High-Quality Finishes

Precision metal fabricators can achieve impeccable finishes on metal surfaces, ranging from smooth and polished to textured and matte. The ability to create high-quality finishes enhances the aesthetic appeal of the end product, making it visually appealing and marketable.

5. Consistency and Accuracy

One of the key advantages of precision metal fabrication is the ability to achieve consistent and accurate results. The use of advanced technology and skilled craftsmanship ensures that each product meets the specified dimensions and tolerances, minimizing errors and rejects.

Choosing the Right Precision Metal Fabricator

When selecting a precision metal fabricator for your project, consider the following factors:

1. Experience and Expertise

Look for a fabricator with a proven track record of experience and expertise in the specific industry or application you require. They should have a portfolio of successful projects and a deep understanding of the materials and processes involved.

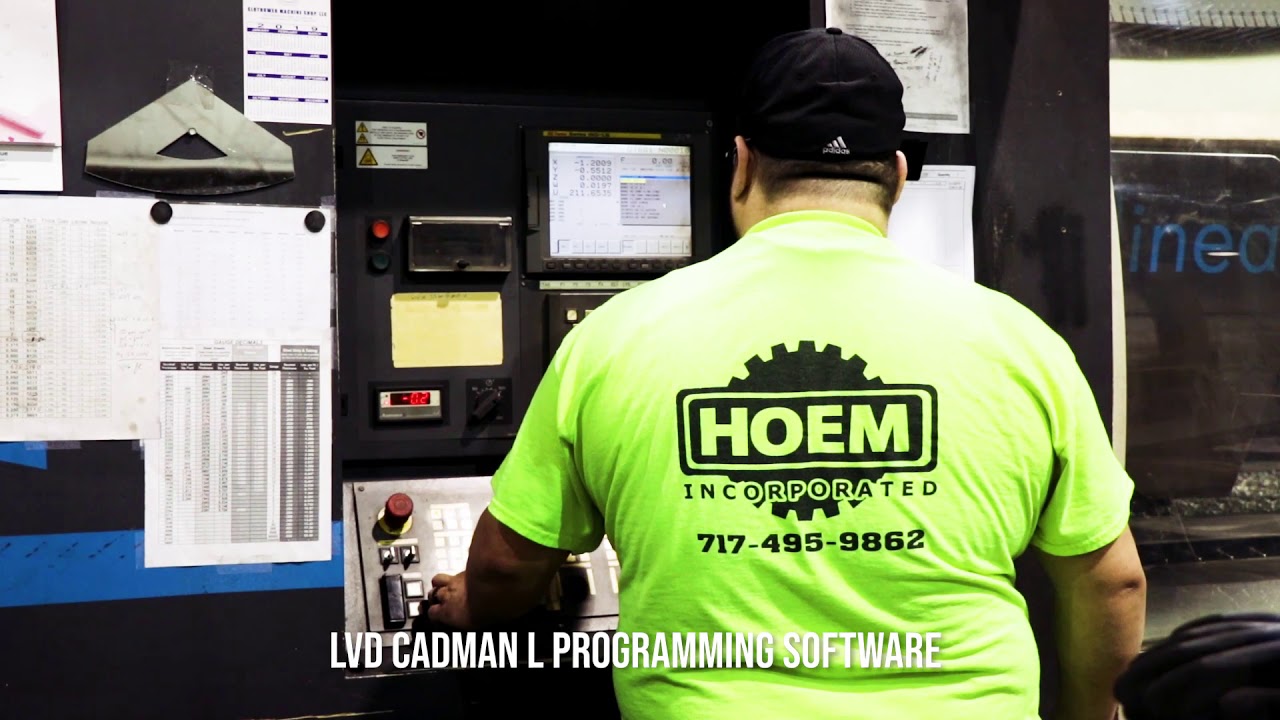

2. Equipment and Technology

Ensure that the fabricator has access to modern equipment and technology to achieve the desired precision and quality. Advanced machinery and software can enhance the efficiency and accuracy of the fabrication process.

3. Quality Control Measures

Ask about the fabricator’s quality control measures and certifications. A reliable fabricator should have stringent quality checks in place to ensure that each product meets the highest standards.

4. Timeliness and Flexibility

Consider the fabricator’s ability to meet deadlines and accommodate changes or modifications during the fabrication process. Timeliness and flexibility are crucial factors, especially in industries with tight project schedules.

5. Customer Reviews and References

Read customer reviews and seek references from past clients to gauge the fabricator’s reputation and customer satisfaction. Positive feedback and recommendations indicate a reliable and trustworthy fabricator.

In conclusion, precision metal fabricators are the master craftsmen who can transform raw metal materials into exquisite, functional, and durable products. Their expertise, attention to detail, and advanced fabrication techniques make them an integral part of various industries. Whether you need intricate decorative pieces or complex industrial components, precision metal fabricators are the key to realizing your vision.

“Laser Precision: Mastering Metal Fabrication”

Video Source : Precision Metal Fabricators

List of Precision Metal Fabricators

Precision Metal Fabricators

| Company Name | Location | Years of Experience | Specializations |

|---|---|---|---|

| ABC Metalworks | Chicago, IL | 30+ | Sheet metal fabrication, CNC machining, Welding |

| DEF Fabrication Solutions | Los Angeles, CA | 25+ | Custom metal fabrication, Laser cutting, Powder coating |

| GHI Precision Industries | New York, NY | 40+ | Prototyping, Precision machining, Assembly |

| JKL Metalcraft | Houston, TX | 20+ | Sheet metal forming, Robotic welding, Surface finishing |

Precision metal fabrication is a specialized field that requires expertise, advanced machinery, and years of experience. The table above showcases some of the leading precision metal fabricators in the industry.

ABC Metalworks, based in Chicago, IL, boasts over 30 years of experience in the field. They specialize in sheet metal fabrication, CNC machining, and welding. Their commitment to quality and precision has made them a trusted partner for various industries.

DEF Fabrication Solutions, located in Los Angeles, CA, has been providing top-notch custom metal fabrication services for over 25 years. Their expertise lies in laser cutting, powder coating, and various other fabrication techniques. They are known for their attention to detail and ability to deliver complex projects on time.

GHI Precision Industries, situated in the heart of New York, NY, has an impressive track record of over 40 years in the industry. They excel in prototyping, precision machining, and assembly. With their state-of-the-art facilities and seasoned team, they have successfully executed numerous high-profile projects.

JKL Metalcraft, based in Houston, TX, brings over 20 years of experience to the table. They specialize in sheet metal forming, robotic welding, and surface finishing. Their dedication to innovation and use of cutting-edge technologies have positioned them as a reliable partner for clients seeking intricate metal fabrications.

These precision metal fabricators exemplify the highest standards of craftsmanship and are renowned for their ability to meet the most demanding project requirements.