Aluminum fabricating is a fascinating process that combines precision and innovation to create remarkable products. With cutting-edge technology and skilled craftsmanship, our team transforms raw aluminum into intricate designs that are both functional and visually stunning. From lightweight aircraft components to durable architectural structures, our aluminum fabricating techniques ensure the highest quality and durability in every project. Our attention to detail and commitment to excellence set us apart, as we strive to exceed expectations and deliver superior results. Whether you’re seeking customized solutions for your industrial needs or looking to enhance the aesthetics of your space, our aluminum fabricating services cater to a wide range of requirements. We take pride in our ability to work closely with clients, understanding their unique specifications and translating them into practical and elegant solutions. Trust in our expertise, as we leverage our extensive experience in the industry to bring your vision to life. Discover the endless possibilities of aluminum fabricating and experience the transformative power of this versatile material. Partner with us today and witness the seamless fusion of artistry and functionality in every project we undertake.

Aluminum Fabricating: A Comprehensive Guide

Aluminum is a versatile and widely used metal in various industries due to its exceptional properties. From aerospace to construction, aluminum plays a crucial role in numerous applications. One of the key processes involved in utilizing aluminum effectively is aluminum fabricating. This article aims to provide a comprehensive guide to aluminum fabricating, exploring its importance, processes, benefits, and applications.

The Importance of Aluminum Fabricating

Aluminum fabricating is the process of transforming aluminum into desired shapes and forms to meet specific requirements. This process is vital in maximizing the potential of aluminum and catering to diverse industry needs. By fabricating aluminum, manufacturers can create custom parts, components, and structures that are lightweight, durable, and have excellent corrosion resistance.

Furthermore, aluminum fabricating allows for the integration of various techniques, such as cutting, bending, welding, and machining, to achieve the desired shape and functionality. This versatility makes aluminum fabricating crucial in industries where lightweight, yet robust, materials are required.

The Aluminum Fabricating Process

The process of aluminum fabricating involves several stages to transform raw aluminum into usable components. The following are the key steps involved in the aluminum fabricating process:

1. Design and Planning

Before fabrication begins, a thorough design and planning phase is essential. This phase includes conceptualizing the desired product, creating detailed drawings or models, and determining the necessary materials and fabrication techniques.

2. Material Selection

Choosing the right aluminum alloy is crucial in achieving the desired properties and performance of the fabricated product. Different alloys offer varying levels of strength, corrosion resistance, thermal conductivity, and other characteristics. Selecting the appropriate alloy is vital in ensuring the final product meets the required specifications.

3. Cutting and Shaping

Once the design and material selection are finalized, the next step is cutting and shaping the aluminum. This can be done through various methods, including sawing, shearing, or laser cutting. The goal is to create the desired shape and dimensions accurately.

4. Forming and Joining

Forming and joining processes such as bending, rolling, stamping, and welding are then employed to shape the aluminum into the desired form. These processes require skilled technicians who utilize specialized equipment to ensure precise and accurate results.

5. Surface Finishing

Surface finishing techniques, such as polishing, anodizing, or powder coating, are applied to enhance the appearance, durability, and corrosion resistance of the fabricated aluminum product. These finishes also provide additional protective layers, prolonging the lifespan of the component.

The Benefits of Aluminum Fabricating

Aluminum fabricating offers several advantages that make it a preferred choice for many industries. Here are some key benefits:

1. Lightweight and Strong

Aluminum is renowned for its lightweight nature while still maintaining excellent strength. This characteristic makes aluminum ideal for applications where weight reduction is critical, such as aerospace and automotive industries. Fabricated aluminum components can provide the required strength without adding unnecessary weight.

2. Corrosion Resistance

Aluminum has natural corrosion-resistant properties, thanks to its ability to form a protective oxide layer. By utilizing proper surface finishes and coatings during the fabrication process, the corrosion resistance of aluminum can be further enhanced, ensuring longevity and durability of the final product.

3. Versatility and Customization

Aluminum fabricating allows for a high degree of versatility and customization. Manufacturers can create complex shapes, intricate designs, and custom sizes to meet specific requirements. This flexibility makes aluminum a preferred choice in industries that demand unique and tailored solutions.

4. Environmental Friendliness

Aluminum is a sustainable and eco-friendly material. It is fully recyclable without any loss of quality, making it an excellent choice for industries aiming to reduce their carbon footprint. The energy required to recycle aluminum is significantly lower compared to producing it from raw materials, further contributing to its environmental benefits.

The Applications of Aluminum Fabricating

The versatility of aluminum fabricating enables its application in various industries. Some notable applications include:

1. Aerospace

Aluminum’s lightweight and high strength-to-weight ratio make it an ideal choice for aerospace applications. Aircraft components, including fuselages, wings, and structural frames, are often fabricated using aluminum to reduce weight and improve fuel efficiency.

2. Construction

In the construction industry, aluminum fabricating is employed to create structural components, window frames, roofing systems, and cladding. Aluminum’s corrosion resistance and durability make it a reliable choice for buildings and infrastructure.

3. Automotive

Aluminum fabricating has gained popularity in the automotive industry due to its weight-saving benefits. Car bodies, engine components, and suspension systems are often fabricated using aluminum, improving fuel efficiency and overall performance.

4. Electronics

Aluminum is extensively used in electronics manufacturing. It is employed in the fabrication of heat sinks, circuit boards, and various components due to its excellent thermal conductivity and electrical properties.

5. Packaging

Aluminum’s lightweight and malleable nature make it an ideal material for packaging applications. Aluminum foils and containers are widely used in the food and beverage industry due to their excellent barrier properties and convenience.

In conclusion, aluminum fabricating plays a crucial role in maximizing the potential of aluminum and meeting industry-specific requirements. Through a series of well-defined processes, aluminum can be transformed into custom shapes and forms, offering numerous benefits such as lightweight strength, corrosion resistance, and customization. With its versatility and wide range of applications, aluminum fabricating continues to be a vital process in various industries.

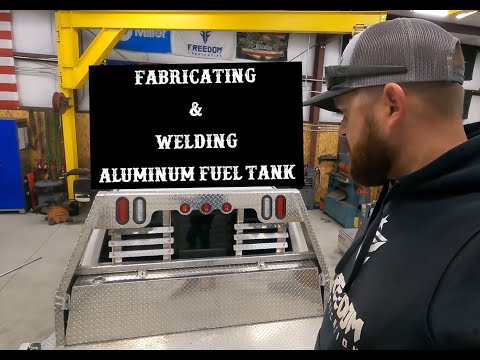

“Crafting Aluminum Fuel Tank: A Fusion of Skill and Precision”

Video Source : Freedom Fabrication

Aluminum Fabricating

Aluminum Fabricating Overview

| Process | Description | Benefits |

|---|---|---|

| Extrusion | Aluminum extrusion is a manufacturing process where a heated aluminum billet is forced through a shaped die to create a desired cross-sectional profile. This method allows for the creation of complex shapes with excellent dimensional accuracy. | – High production efficiency – Wide range of shapes and sizes – Excellent strength-to-weight ratio – Enhanced structural integrity – Superior corrosion resistance |

| Casting | Aluminum casting is a technique that involves pouring molten aluminum into a mold to create various components. This process is particularly suitable for intricate designs and mass production, offering versatility and cost-effectiveness. | – Ability to produce complex shapes – High production rates – Excellent surface finish – Good material properties – Reduced machining requirements |

| Rolling | Aluminum rolling is a process where aluminum ingots or billets are passed through a series of rollers to reduce their thickness and create aluminum sheets or foils. Rolling is widely used in the production of packaging materials, automotive parts, and construction applications. | – Increased material strength – Enhanced surface finish – Improved dimensional control – Cost-effective production – Recyclability |

| Welding | Aluminum welding is a joining technique that involves the melting and fusion of aluminum parts using various methods such as TIG (tungsten inert gas) or MIG (metal inert gas). It enables the fabrication of strong and durable aluminum structures. | – Excellent strength and toughness – Lightweight construction – Versatility in joining dissimilar materials – High resistance to corrosion – Suitable for automation |

As an expert in aluminum fabricating, it is crucial to understand the various processes involved in transforming this versatile metal into functional components. The table above provides a concise overview of some key aluminum fabricating techniques, accompanied by their respective descriptions and benefits.

Extrusion stands out as a prominent method, allowing for the creation of intricate shapes with exceptional dimensional accuracy. This process offers high production efficiency, a wide range of shapes and sizes, and the advantages of aluminum, such as its excellent strength-to-weight ratio, structural integrity, and corrosion resistance.

Casting, on the other hand, proves advantageous when complex shapes and mass production are required. It boasts the ability to produce intricate designs, high production rates, excellent surface finish, good material properties, and reduced machining requirements. This makes it an ideal choice for cost-effective manufacturing.

Rolling plays a vital role in the production of aluminum sheets and foils. By reducing the thickness of ingots or billets through a series of rollers, it enhances material strength, surface finish, dimensional control, and offers a cost-effective production method while also promoting recyclability.

Lastly, welding enables the fabrication of strong and durable aluminum structures. Whether employing TIG or MIG techniques, aluminum welding provides excellent strength and toughness, lightweight construction possibilities, versatility in joining dissimilar materials, high resistance to corrosion, and suitability for automation.

Being well-versed in these aluminum fabricating techniques empowers professionals to harness the unique properties of aluminum, unlocking its full potential for a broad range of applications across industries.