Brass fabrication is a remarkable process that combines artistry and precision engineering to transform raw brass materials into exquisite creations. With a rich history dating back centuries, this age-old craft continues to captivate enthusiasts and professionals alike. From intricate designs to intricate details, brass fabrication offers endless possibilities for creating stunning and unique pieces. Whether it be delicate jewelry, ornate sculptures, or functional architectural elements, this versatile metal can be shaped and manipulated to suit any vision.

What sets brass fabrication apart is the meticulous attention to quality and the dedication to craftsmanship. Skilled artisans and technicians work meticulously, employing a myriad of techniques such as cutting, bending, soldering, and polishing to bring brass to life. The malleability of brass allows for intricate engravings and embossing, resulting in extraordinary textures and finishes that are truly one-of-a-kind.

Furthermore, brass fabrication offers numerous advantages beyond its aesthetic appeal. Brass is highly durable, resistant to corrosion, and possesses excellent conductivity, making it a preferred choice for electrical applications. Its versatility extends to various industries, including automotive, aerospace, and construction, where its strength and reliability are highly valued.

Whether you are an admirer of fine craftsmanship or an industry professional seeking reliable and visually striking solutions, brass fabrication is a world waiting to be discovered. Immerse yourself in the artistry and precision of this ancient craft, and witness the transformation of a simple metal into extraordinary creations that stand the test of time.

2023 Trending Brass Fabrication

| Process | Description | Advantages |

|---|---|---|

| Extrusion | The process of shaping brass by forcing it through a die under high pressure. | Produces complex shapes with excellent dimensional control and surface finish. |

| Casting | Melting brass and pouring it into a mold to obtain the desired shape. | Allows for the production of intricate designs and large-scale components. |

| Machining | Using cutting tools to remove material and shape the brass into the desired form. | Offers high precision and the ability to create custom parts with tight tolerances. |

| Forming | Bending or shaping brass sheets or plates to create various products. | Enables the production of curved or contoured components with structural integrity. |

| Welding | Joining brass pieces together by melting the material and fusing them. | Provides strong and durable connections, suitable for load-bearing applications. |

Brass fabrication in 2023 is expected to witness a surge in popularity, with various techniques being employed to create high-quality components. Among the most trending methods are extrusion, casting, machining, forming, and welding.

Extrusion, a process where brass is forced through a die under high pressure, offers exceptional control over shape and surface finish. This technique is especially favored for producing intricate and complex brass components with precise dimensional accuracy.

Casting, on the other hand, involves melting brass and pouring it into molds to achieve the desired shapes. This method is highly versatile, enabling the creation of intricate designs and large-scale brass structures.

Machining, a traditional yet indispensable technique, involves the use of cutting tools to shape brass by removing material. It offers unparalleled precision and is often employed to produce custom brass parts with tight tolerances.

Forming, another popular method, involves bending or shaping brass sheets or plates to create various products. This technique is particularly useful for fabricating curved or contoured components while maintaining structural integrity.

Lastly, welding plays a crucial role in brass fabrication, allowing the joining of brass pieces through the melting and fusion of material. This process ensures strong and durable connections, making it suitable for load-bearing applications.

In conclusion, the brass fabrication industry in 2023 is witnessing an upsurge in popularity, with techniques such as extrusion, casting, machining, forming, and welding being at the forefront. These methods offer a wide range of advantages, enabling the production of intricate designs, custom parts, and structurally sound brass components.

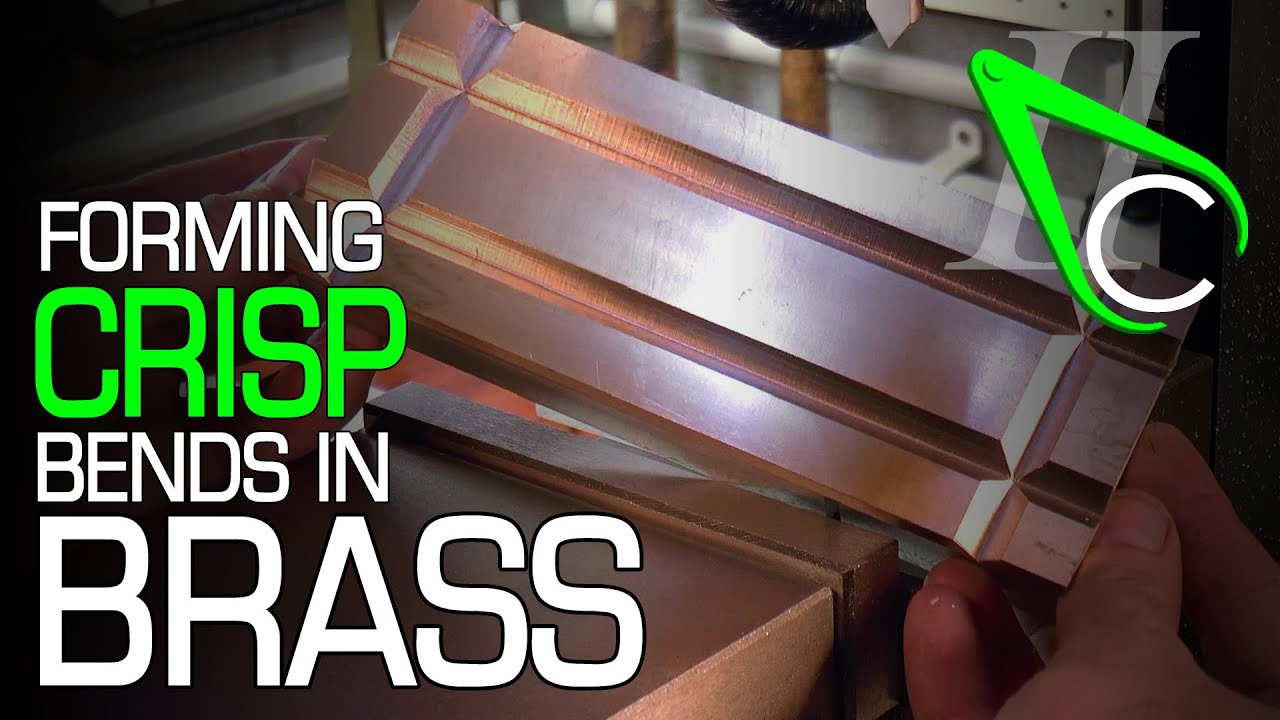

“Bending Brass with Ease: Mastering Crisp Curves”

Brass Fabrication: A Comprehensive Guide

Brass, a versatile alloy composed of copper and zinc, has been used for centuries in various industries. Its unique properties make it an ideal material for fabrication. In this article, we will delve into the world of brass fabrication, exploring its applications, processes, benefits, and limitations.

What is Brass Fabrication?

Brass fabrication refers to the process of shaping brass into desired forms and structures. It involves several techniques, including cutting, bending, welding, and shaping, to create intricate and functional components. Brass is favored for fabrication due to its malleability, corrosion resistance, and attractive appearance.

The Applications of Brass Fabrication

Brass fabrication finds its application in a wide range of industries, including:

1. Architecture: Brass fabrication is commonly used in architectural projects due to its aesthetic appeal and durability. It is often employed in the creation of decorative elements, such as handrails, door handles, and lighting fixtures.

2. Automotive: The automotive industry extensively relies on brass fabrication for manufacturing various components, including radiator cores, fuel tanks, connectors, and electrical terminals. Brass’s high thermal conductivity and corrosion resistance are particularly advantageous in this sector.

3. Electrical and Electronics: Brass is an excellent electrical conductor, making it an ideal material for electrical and electronic applications. It is widely used in the fabrication of connectors, terminals, switches, and various other electrical components.

4. Plumbing: Brass fabrication plays a vital role in the plumbing industry. Its corrosion resistance, antimicrobial properties, and ability to withstand high temperatures make it an ideal choice for fittings, valves, faucets, and pipes.

5. Musical Instruments: Brass fabrication is deeply intertwined with the production of musical instruments, such as trumpets, saxophones, and trombones. The malleability and unique acoustic properties of brass allow for the creation of instruments with rich and resonant sounds.

The Brass Fabrication Process

Brass fabrication involves several key steps:

1. Design and Planning: The process begins with designing the desired component or structure. Computer-aided design (CAD) software is often used to create precise and detailed models.

2. Material Selection: Choosing the appropriate brass alloy is crucial for successful fabrication. Factors such as desired properties, cost, and availability must be considered during this stage.

3. Cutting: Brass sheets or rods are cut into specific dimensions using various techniques, such as sawing, shearing, or laser cutting. This step ensures the raw material is ready for further processing.

4. Forming and Shaping: Brass can be bent, rolled, or pressed into the desired shape using techniques like CNC machining, stamping, or bending. This step gives the component its final form.

5. Joining: Joining brass components is often done through welding or soldering. These processes require skilled technicians to ensure strong and durable bonds.

6. Finishing: The final step involves surface treatment, such as polishing, buffing, or plating, to enhance the appearance and protect the brass from corrosion.

The Benefits and Limitations of Brass Fabrication

Benefits:

Brass fabrication offers numerous advantages:

1. Versatility: Brass can be easily shaped and molded into various forms, accommodating a wide range of design requirements.

2. Aesthetic Appeal: The golden hue of brass adds a touch of elegance and sophistication to any finished product.

3. Corrosion Resistance: Brass exhibits excellent resistance to corrosion, making it suitable for both indoor and outdoor applications.

4. Durability: Brass is a durable material that can withstand harsh environmental conditions and heavy use.

Limitations:

However, brass fabrication also has a few limitations:

1. Cost: Brass is relatively more expensive compared to other metals, which can affect the overall cost of fabrication projects.

2. Weight: Brass is denser than many other materials, resulting in heavier components that may not be suitable for certain applications.

3. Machinability: Brass can be challenging to machine due to its tendency to work-harden, requiring specialized equipment and skilled operators.

In Conclusion

Brass fabrication offers a wide range of applications and benefits, making it a popular choice across various industries. Understanding the fabrication process, along with its advantages and limitations, is crucial for achieving successful outcomes. Whether it’s architectural embellishments, automotive components, electrical connectors, or musical instruments, brass fabrication continues to shape our world with its timeless appeal and functional properties.

Brass Fabrication

- Sheet Metal Cutting and Bending

- Brass Tube and Pipe Fabrication

- Brass Casting and Forging

- Welding and Joining Brass Components

- CNC Machining of Brass Parts

- Surface Finishing and Polishing

- Custom Fabrication of Brass Components