Copper fabrication is a fascinating process that combines intricate craftsmanship with the versatility of this remarkable metal. With its rich history spanning thousands of years, copper has been widely used in various industries, from architecture to electronics. This fabrication technique involves transforming raw copper into unique and functional objects through a meticulous series of cutting, shaping, and joining methods. Skilled artisans meticulously manipulate this malleable material, breathing life into extraordinary creations that showcase the inherent beauty and durability of copper. Whether it’s a stunning sculpture, a functional piece of artwork, or a complex electrical component, the art of copper fabrication is a testament to human creativity and ingenuity. From the careful selection of the finest copper sheets to the precise bending and soldering techniques, each step in the fabrication process is executed with precision and expertise. The end result is a masterpiece that not only showcases the versatility and elegance of copper but also stands as a testament to the dedication and skill of the craftsmen involved. Discover the world of copper fabrication and immerse yourself in the artistry and passion behind this timeless craft.

2023 Trending Copper Fabrication

| Process | Description | Advantages |

|---|---|---|

| Soldering | Soldering is a widely used technique in copper fabrication, involving joining two or more copper pieces using a filler metal that melts at a lower temperature than the base metal. It provides excellent electrical conductivity and is frequently used in electronic circuitry. | – Strong bond formation – Low cost – Suitable for intricate designs |

| Brazing | Brazing is a process where a filler metal with a melting point above 450°C is used to join copper components. It offers superior strength and durability, making it ideal for applications that require high mechanical integrity. | – High joint strength – Ability to join dissimilar metals – Enhanced resistance to corrosion |

| Welding | Welding involves the fusion of two copper pieces using heat and often a filler metal. It is commonly used in structural applications due to its ability to create strong and permanent bonds. Various welding techniques, such as TIG and MIG, can be employed depending on the specific requirements. | – Excellent joint strength – Versatility in applications – Possibility to automate the process |

| Forming | Copper can be formed into various shapes through processes like bending, rolling, and deep drawing. This versatility makes it highly desirable for applications where complex geometries are required, such as in the manufacturing of copper pipes, tubes, and electrical connectors. | – Ability to achieve intricate designs – High resistance to corrosion – Excellent electrical conductivity |

| Etching | Etching is a process used to selectively remove copper from a surface, creating intricate patterns or designs. It is commonly applied in the production of printed circuit boards (PCBs) and decorative items. Various etching techniques, like chemical and laser etching, offer precise control over the material removal. | – High precision and accuracy – Ability to create intricate designs – Cost-effective for mass production |

As the copper fabrication industry progresses into 2023, these processes continue to dominate the field. Soldering remains a go-to technique for electronics, offering reliable connections and cost-effectiveness. Brazing, with its exceptional strength and resistance to corrosion, finds extensive use in critical applications. Welding, known for its versatility and strength, is widely employed in structural projects. The ability to shape copper through forming processes enables the creation of intricate designs and electrical components. Lastly, etching techniques provide precise and efficient means for material removal, crucial in the production of PCBs and decorative items.

With ongoing advancements in technology and evolving customer demands, copper fabrication techniques are continuously refined to meet the industry’s evolving requirements.

Copper Crafting: Unleashing Your Creative Potential

The Art of Copper Fabrication: Creating Beauty and Functionality

Copper fabrication is a centuries-old craft that combines the beauty and versatility of copper with the skills of skilled artisans. From intricate sculptures to functional household items, copper fabrication is a fascinating process that transforms raw copper into works of art. In this article, we will explore the art of copper fabrication, its history, techniques, and the stunning creations it produces.

A Brief History of Copper Fabrication

Copper fabrication has a rich history dating back thousands of years. The use of copper for decorative and functional purposes can be traced back to ancient civilizations such as the Egyptians, Greeks, and Romans. These civilizations recognized the aesthetic appeal and durability of copper, using it to create jewelry, statues, and even weapons.

In the Middle Ages, copper fabrication became more refined, with craftsmen developing techniques to shape and manipulate copper into intricate designs. The Renaissance period witnessed a surge in copper fabrication, as artists and architects embraced the material for its malleability and ability to hold fine details.

Today, copper fabrication continues to evolve, with modern craftsmen combining traditional techniques with cutting-edge technology to create stunning pieces that blend tradition with innovation.

The Copper Fabrication Process

The copper fabrication process involves several steps, each requiring skill and precision. Here is an overview of the process:

1. Design and Planning

The first step in copper fabrication is the design and planning phase. This involves conceptualizing the piece, creating sketches or digital renderings, and determining the dimensions and materials required. Attention to detail is crucial in this stage to ensure the final product meets the client’s expectations.

2. Material Selection and Preparation

Once the design is finalized, the next step is selecting the appropriate copper material. Copper sheets or bars are commonly used in fabrication, and the choice depends on the desired outcome. The selected copper is then cleaned and prepared for shaping.

3. Shaping and Forming

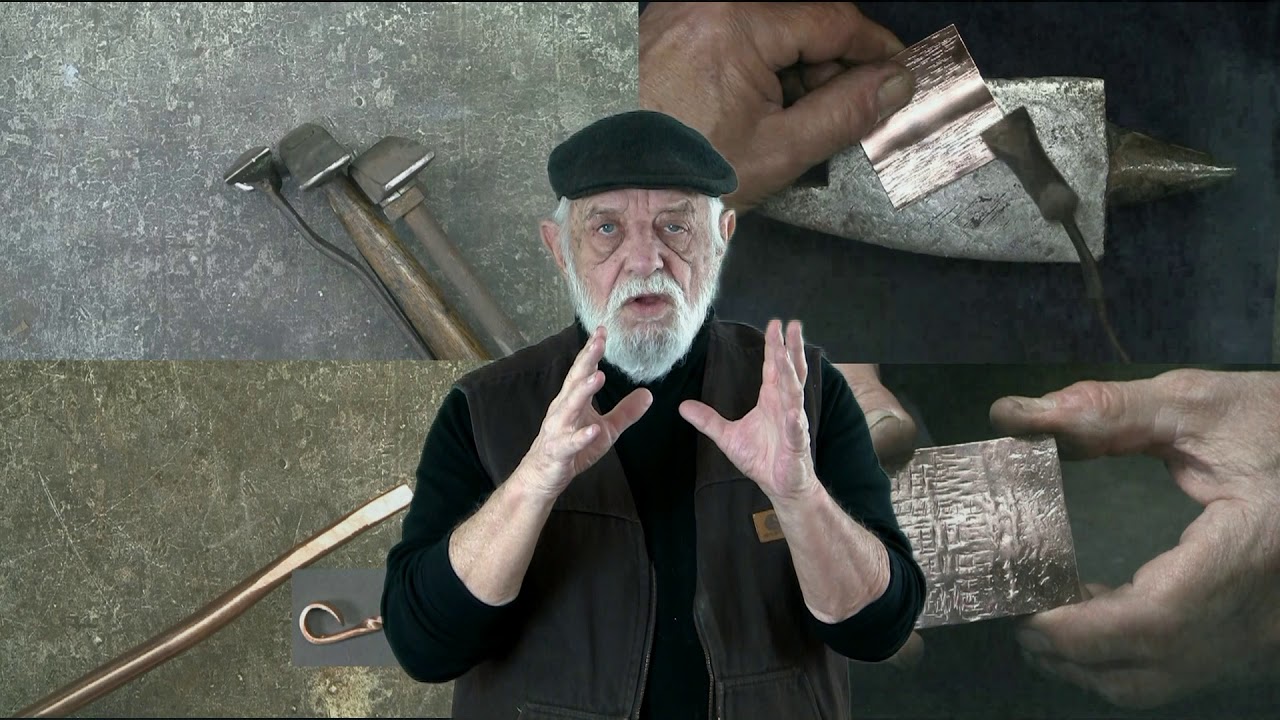

This is where the true artistry of copper fabrication comes into play. Skilled craftsmen use various techniques to shape and form the copper into the desired design. Traditional methods such as hammering, bending, and soldering are combined with modern tools like hydraulic presses and laser cutters to achieve intricate details and complex shapes.

4. Surface Finishing

Once the copper piece is shaped, it undergoes surface finishing to enhance its appearance and protect it from corrosion. This can involve techniques such as polishing, patination, or applying protective coatings to achieve the desired finish.

5. Assembly and Installation

If the copper piece requires assembly, this step involves joining different components together using solder or other suitable methods. Once assembled, the final piece is carefully installed, whether it’s a sculpture, architectural element, or a functional item like a copper sink or range hood.

The Beauty and Versatility of Copper Fabrication

Copper fabrication offers a unique combination of beauty and versatility. Copper’s warm, reddish-brown color and natural patina make it an aesthetically pleasing material that adds a touch of elegance to any space. Additionally, copper is highly malleable, allowing craftsmen to create intricate and detailed designs that other metals may not allow.

From ornate architectural elements like domes and cupolas to delicate jewelry and wall art, copper fabrication can be tailored to suit a wide range of applications. Its durability and resistance to corrosion make it suitable for both indoor and outdoor use, ensuring that copper creations withstand the test of time.

The Enduring Appeal of Copper Fabrication

Despite advances in technology and the availability of alternative materials, copper fabrication continues to captivate artisans and homeowners alike. The enduring appeal of copper lies in its ability to evoke a sense of timeless beauty and craftsmanship. Each copper creation tells a story, reflecting the skill and dedication of the craftsmen who brought it to life.

Whether it’s a grand architectural element or a small decorative item, copper fabrication adds a touch of elegance and sophistication to any space. Its versatility and ability to blend with various design styles make it a favorite among interior designers and architects who seek to create unique and captivating environments.

In conclusion, copper fabrication is an art form that combines the beauty of copper with the skill of craftsmen to create breathtaking pieces. From ancient civilizations to modern-day artisans, copper has stood the test of time as a material of choice for its aesthetic appeal and versatility. Whether it’s a decorative sculpture or a functional item, copper fabrication continues to enchant and inspire with its ability to transform raw copper into objects of art.

Copper Fabrication

- Copper sheet metal cutting

- Copper sheet metal bending

- Copper sheet metal welding

- Copper sheet metal punching

- Copper sheet metal rolling

- Copper sheet metal stamping

- Copper sheet metal forming

- Copper sheet metal shearing

Frequently Asked Questions

What is copper fabrication?

Copper fabrication refers to the process of shaping and manipulating copper into desired forms or products. It involves various techniques such as cutting, bending, welding, and soldering to create finished copper components or structures.

What are the benefits of copper fabrication?

Copper fabrication offers several benefits. Firstly, copper is a highly conductive material, making it ideal for electrical applications. It also has excellent corrosion resistance, making it suitable for outdoor and marine environments. Additionally, copper is easy to work with, allowing for complex shapes and designs. Lastly, copper has aesthetic appeal, making it a popular choice for decorative purposes.

What are common applications of copper fabrication?

Copper fabrication is used in various industries and applications. It is commonly used in electrical wiring, connectors, and circuit boards due to its high conductivity. Copper pipes and tubing are widely used in plumbing and HVAC systems. In the construction industry, copper fabrication is employed for roofing, gutters, and architectural elements. Additionally, copper fabrication is utilized in manufacturing equipment, heat exchangers, and decorative items.