Sign fabrication is an artform that seamlessly combines creativity, precision, and craftsmanship to transform your ideas into stunning visual masterpieces. With meticulous attention to detail and a passion for excellence, our team of skilled artisans brings your vision to life, making your brand or business stand out from the competition. From conceptualization to installation, we are committed to delivering top-notch signage solutions that captivate, inform, and leave a lasting impression on your target audience. Whether you’re looking for eye-catching illuminated signs that command attention day and night, or sleek dimensional lettering that exudes sophistication, our experienced professionals employ state-of-the-art techniques and cutting-edge materials to create high-quality and durable signage for both indoor and outdoor applications. We understand that every project is unique, and that’s why we offer personalized consultations to ensure that our fabrication process aligns perfectly with your specific goals and requirements. With our expertise and unwavering commitment to customer satisfaction, we guarantee that your custom signs will not only meet but exceed your expectations. Trust us to elevate your brand’s visibility and make a bold statement that leaves a lasting impression.

What is Sign Fabrication?

Sign fabrication is the process of creating custom signs using various materials and techniques. It involves designing, manufacturing, and installing signs for businesses, organizations, and events. High-quality signs are essential for effective branding, advertising, and wayfinding.

The Importance of High-Quality Signs

Effective signs play a crucial role in attracting customers, conveying information, and enhancing brand recognition. They serve as a first impression for potential customers and can make a lasting impact. High-quality signs are visually appealing, durable, and convey the intended message clearly.

When it comes to branding, signs are an integral part of a company’s identity. They help create a consistent and recognizable image, which is vital for building trust and establishing a strong presence in the market. A professional-looking sign can significantly improve the perceived value of a business.

Furthermore, well-designed and strategically placed signs can drive foot traffic and increase sales. They act as silent salespeople, promoting products, services, and special offers. A clear and eye-catching sign can attract attention and entice potential customers to visit a store or make a purchase.

The Sign Fabrication Process

Sign fabrication involves several steps to transform an idea into a finished sign:

1. Design

The design phase is crucial for creating a visually appealing and effective sign. Designers work closely with clients to understand their goals and preferences. They consider factors such as the target audience, location, and brand identity. Once the design is finalized, it is sent to the fabrication team.

2. Material Selection

Choosing the right materials is essential for creating a durable and visually appealing sign. The fabrication team selects materials based on factors such as the sign’s purpose, location, and budget. Common materials used in sign fabrication include metal, acrylic, PVC, wood, and vinyl.

3. Manufacturing

During the manufacturing phase, the fabrication team brings the design to life. They use various techniques such as cutting, welding, painting, and printing to create the different components of the sign. Attention to detail and precision are crucial to ensure the final product meets the client’s expectations.

4. Installation

Installation is a critical step in the sign fabrication process. The fabrication team ensures the sign is securely mounted and positioned for maximum visibility. They consider factors such as the surrounding environment, lighting conditions, and local regulations. Proper installation ensures the sign’s longevity and effectiveness.

5. Maintenance and Repair

After installation, regular maintenance is necessary to keep the sign in optimal condition. Cleaning, repainting, and replacing damaged components are some common maintenance tasks. In case of any damage or malfunction, timely repairs are essential to avoid a negative impact on the business’s image and visibility.

The Benefits of Professional Sign Fabrication

While some businesses may consider creating signs in-house or opting for cheaper alternatives, professional sign fabrication offers numerous benefits:

Expertise and Experience: Professional sign fabricators have the knowledge and experience to create high-quality signs that effectively communicate a business’s message and brand identity.

Customization: Professional sign fabricators can create unique, custom-designed signs that align with a business’s specific requirements and branding guidelines.

Durability: Professionally fabricated signs are made to withstand various weather conditions and last longer compared to DIY or low-quality alternatives.

Compliance: Professional sign fabricators are well-versed in local regulations and ensure that the signs they create comply with all relevant codes and standards.

Cost-Effectiveness: While professional sign fabrication may initially seem more expensive, it can save businesses money in the long run due to the durability and effectiveness of the signs.

In Conclusion

Sign fabrication is a crucial process for creating high-quality signs that effectively convey a business’s message and enhance its visibility. From design to installation, each step requires expertise and attention to detail. Investing in professional sign fabrication can provide businesses with durable, visually appealing signs that leave a lasting impression on customers.

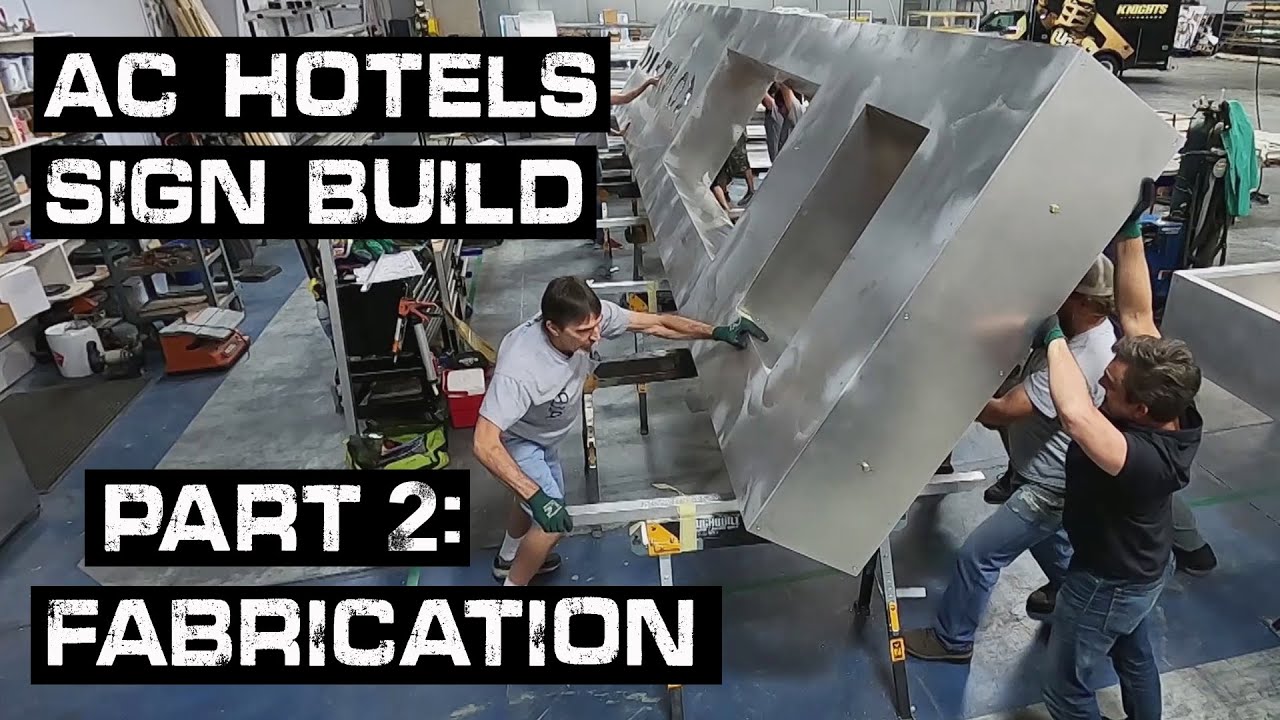

AC Hotels Sign Build Part 2: Crafting the Iconic Design

Video Source : Media 1 Wrap This

Sign Fabrication

Sign Fabrication Table

| Sign Type | Material | Production Technique | Cost |

|---|---|---|---|

| Acrylic Signs | High-quality acrylic sheets | Laser cutting and engraving | Medium to high |

| Aluminum Signs | Durable aluminum panels | Screen printing or vinyl graphics | Medium |

| Wooden Signs | Natural wood or engineered wood | CNC routing and hand painting | Medium to high |

| LED Signs | LED modules and light diffuser panels | LED module assembly and wiring | High |

Sign fabrication involves the creation of various types of signs using different materials and production techniques. Each sign type has its unique characteristics and is suitable for specific applications.

Acrylic signs, made from high-quality acrylic sheets, are a popular choice due to their versatility and durability. They are commonly produced using laser cutting and engraving techniques, allowing for precise and intricate designs. Acrylic signs offer a professional appearance and are suitable for indoor and outdoor use. However, their production cost tends to be medium to high.

Aluminum signs, on the other hand, are known for their durability and weather resistance. These signs are typically made from durable aluminum panels and can be produced using either screen printing or vinyl graphics. Aluminum signs are widely used for outdoor signage, as they can withstand harsh weather conditions. They offer a cost-effective option with a medium production cost.

Wooden signs provide a more rustic and traditional look. They are crafted from natural wood or engineered wood materials and are produced using CNC routing and hand painting techniques. Wooden signs are popular for businesses seeking a warm and inviting aesthetic. Their production cost ranges from medium to high, depending on the complexity of the design and finishing.

LED signs have gained immense popularity in recent years due to their eye-catching visual appeal. These signs utilize LED modules and light diffuser panels to create vibrant and illuminated displays. LED signs are often used for advertising and attracting attention in both indoor and outdoor settings. However, their production cost tends to be high due to the intricate assembly and wiring involved.

When choosing a sign fabrication method, it is important to consider the intended purpose, desired aesthetics, and budget. Consulting with a professional sign manufacturer can help determine the most suitable option based on specific requirements.