Discover the Ultimate Welding Fabrication Table for Precision and Efficiency Are you tired of struggling with unstable work surfaces during your welding projects? Look no further! Our cutting-edge welding fabrication table is designed to revolutionize your welding experience. Crafted with durability, versatility, and precision in mind, this table offers unrivaled stability and adaptability for all your fabrication needs.

Imagine having a worktable that effortlessly accommodates different welding techniques, angles, and materials. Our high-quality fabrication table provides a solid foundation for your projects, ensuring accurate and seamless welds every time. Its adjustable features allow you to customize the table to suit various working heights and angles, promoting comfortable and ergonomic working positions.

Gone are the days of wasting valuable time and effort on makeshift work surfaces. With our welding fabrication table, you can focus on what really matters – achieving professional-grade results. The table’s sturdy construction guarantees exceptional stability, minimizing vibrations and ensuring utmost safety during welding operations.

Whether you are a professional welder or a passionate DIY enthusiast, this welding fabrication table will become your essential companion. Its reliable and efficient design will enhance your productivity, allowing you to complete projects faster and with greater precision.

Invest in our welding fabrication table today and experience the difference it can make in your welding endeavors. Say goodbye to frustration and hello to a new level of excellence in your workshop.

The Importance of a Welding Fabrication Table

When it comes to welding, having a reliable and sturdy welding fabrication table is essential. This specialized table provides a stable work surface for welders to perform their tasks efficiently and safely. In this article, we will explore the importance of a welding fabrication table and the benefits it offers to welders.

1. Enhanced Safety

A welding fabrication table ensures the safety of welders during their work. These tables are designed to withstand high temperatures, sparks, and intense pressure. They are usually made from heat-resistant materials such as steel or cast iron, which can endure the extreme conditions of welding. Additionally, the table’s surface is often coated with a non-flammable material to prevent any accidental fires.

Moreover, welding fabrication tables are equipped with features like clamps and vices that securely hold the workpiece in place. This prevents any movement or slippage during welding, reducing the risk of accidents. The stability provided by these tables allows welders to concentrate on their work without worrying about the safety of their setup.

2. Improved Efficiency

A welding fabrication table plays a crucial role in improving a welder’s efficiency. The table’s flat and level surface provides a stable foundation for precise welding. It enables welders to position their workpiece accurately and maintain the desired angle, resulting in cleaner and more accurate welds.

Furthermore, welding fabrication tables often have built-in features like slots, holes, and grids that allow for easy clamping and alignment of various welding accessories. These features enable welders to set up their tools and equipment quickly, saving valuable time and effort. The efficient setup offered by these tables allows welders to complete their work more efficiently, increasing productivity.

3. Versatility

Welding fabrication tables are designed to accommodate a wide range of welding projects. They come in various sizes and configurations to suit different welding applications. Whether you are working on small-scale projects or large industrial jobs, there is a welding fabrication table that meets your requirements.

Additionally, these tables often have adjustable height and tilt features, allowing welders to customize the table to their preferred working position. This versatility ensures that welders can work comfortably and ergonomically, reducing fatigue and improving their overall performance.

4. Increased Durability

Durability is a crucial factor in any welding equipment, especially when it comes to welding fabrication tables. These tables are built to withstand the harsh conditions of welding, ensuring their longevity and reliability.

Most welding fabrication tables are made from heavy-duty materials like steel or cast iron, which can withstand intense heat, pressure, and heavy loads. They are designed to resist warping, bending, or breaking, even under constant use. This durability ensures that the table remains in excellent condition for extended periods, providing consistent support to welders.

5. Cost-Effectiveness

Investing in a high-quality welding fabrication table is a cost-effective decision for any welder or welding shop. While the initial cost may seem significant, the long-term benefits outweigh the investment.

By providing a safe and efficient work surface, welding fabrication tables reduce the risk of accidents and errors, minimizing any potential costly damages. They also contribute to increased productivity by enabling faster setup and improved welding accuracy.

Furthermore, the durability of these tables ensures that they have a long lifespan, reducing the need for frequent replacements. This, in turn, saves money in the long run as welders do not have to invest in new tables frequently.

Conclusion

A welding fabrication table is an essential tool for any welder. It ensures safety, enhances efficiency, offers versatility, provides durability, and proves to be cost-effective in the long run. Investing in a high-quality welding fabrication table is a wise decision that benefits both the welder and their welding projects.

Whether you are a professional welder or a hobbyist, a reliable welding fabrication table is a valuable asset that improves your welding experience and allows you to achieve superior results.

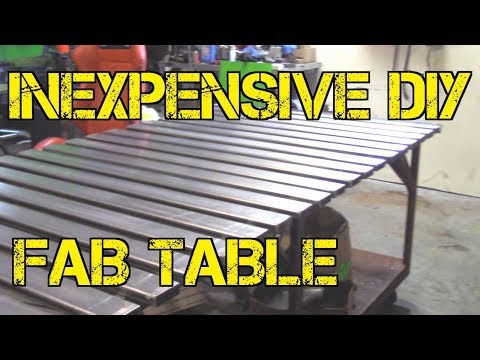

“Frugal and Fun: Craft Your Own Affordable Fab Table!”

Video Source : The Fabrication Series

Welding Fabrication Table

Welding Fabrication Table

| Features | Description |

|---|---|

| Sturdy Construction | The welding fabrication table is built with a robust steel frame, ensuring durability and stability during the welding process. It can withstand heavy loads and intense heat without compromising its structural integrity. |

| Adjustable Height | This table offers adjustable height options, allowing welders to work at their preferred level of comfort. It ensures optimal ergonomics, reducing strain on the body and enhancing productivity. |

| Heat-Resistant Surface | The table’s surface is specifically designed to withstand high temperatures associated with welding. It is often made from heat-resistant materials such as steel or ceramic, preventing damage and ensuring a longer lifespan. |

| Integrated Clamping System | Many welding fabrication tables come equipped with an integrated clamping system. This feature allows welders to secure their workpieces firmly, preventing any movement or distortion during the welding process. |

| Multiple Tool Slots | To enhance efficiency and organization, welding fabrication tables often include multiple tool slots. These slots provide convenient storage for welding tools and accessories, ensuring they are within easy reach whenever needed. |

| Modular Design | Some welding fabrication tables offer a modular design, enabling welders to customize the table according to their specific needs. This versatility allows for easy integration of additional accessories, such as clamps, shelves, or drawers. |

| Portability | For welders who require mobility, certain fabrication tables are designed to be portable. They may feature sturdy wheels or foldable legs, making it effortless to move the table to different locations within the workshop or job site. |

As an expert in welding fabrication, it is crucial to select a high-quality welding fabrication table that meets your specific requirements. The table’s sturdy construction ensures optimal stability and longevity, allowing you to tackle even the most demanding welding projects. With an adjustable height feature, you can customize the table to your preferred working position, ensuring comfort and reducing the risk of strain-related injuries.

The heat-resistant surface of the welding fabrication table is of utmost importance. It protects the table from damage caused by high welding temperatures, guaranteeing that the table will endure and serve you well for years to come. Additionally, an integrated clamping system ensures that your workpieces remain securely in place, enabling precise and accurate welding without any unwanted movement.

To enhance efficiency and organization, opt for a table with multiple tool slots. This feature ensures that all your welding tools and accessories are easily accessible, saving you time and effort during the welding process. Modular design options provide even more flexibility, allowing you to add or remove accessories as needed, thus tailoring the table to your specific workflow.

Lastly, consider the portability of the welding fabrication table. If you require mobility in your welding projects, choose a table that is equipped with wheels or foldable legs. This feature enables you to effortlessly transport the table to different locations within your workshop or job site, ensuring maximum convenience.

Investing in a high-quality welding fabrication table will undoubtedly enhance your welding experience. By considering the features mentioned above, you can select the perfect table that aligns with your needs, providing a reliable and efficient workspace for all your welding endeavors.