Slosh fabrication is a revolutionary process that combines advanced technology with meticulous craftsmanship to create stunning and unique products. With a commitment to excellence, precision, and innovation, our team of skilled artisans brings your vision to life, transforming ordinary materials into extraordinary works of art. Whether you’re looking for custom-made furniture, exquisite jewelry, or one-of-a-kind home decor, our skilled craftsmen use their unmatched expertise to deliver exceptional results that will surpass your expectations. Through our state-of-the-art techniques and attention to detail, we elevate the ordinary, infusing each piece with a touch of magic that captivates the senses. Our unparalleled dedication to quality ensures that every item that leaves our workshop is not only visually stunning but also built to stand the test of time. From the initial design concept to the final finishing touches, we take pride in every step of the meticulous process. Discover the world of slosh fabrication and experience the fusion of art and technology that creates objects that are truly extraordinary.

2023 Trending Slosh Fabrication

| Material | Properties | Applications |

|---|---|---|

| Carbon Fiber Reinforced Polymer (CFRP) | High strength-to-weight ratio, excellent fatigue resistance, corrosion resistant | Aerospace components, automotive parts, sports equipment |

| Titanium Alloy | High strength, lightweight, exceptional heat resistance | Medical implants, aircraft structures, military applications |

| Nanomaterials | Enhanced mechanical, thermal, and electrical properties | Electronics, energy storage, biomedical devices |

| Shape Memory Alloys (SMA) | Ability to return to pre-deformed shape upon heating, excellent fatigue resistance | Robotics, medical devices, automotive industry |

| Biopolymers | Biodegradable, renewable, reduced environmental impact | Packaging materials, medical implants, textile industry |

Slosh fabrication in 2023 is witnessing a fascinating trend towards utilizing advanced materials that offer exceptional properties and vast applications. This table presents some of the most intriguing materials being employed in the field.

Carbon Fiber Reinforced Polymer (CFRP) stands out due to its remarkable strength-to-weight ratio, making it the go-to choice for aerospace components, automotive parts, and sports equipment. Not only does CFRP possess excellent fatigue resistance, but it is also highly corrosion resistant, rendering it ideal for demanding environments.

Another material gaining considerable traction is Titanium Alloy, renowned for its high strength, lightweight nature, and exceptional heat resistance. With these remarkable properties, it finds extensive use in medical implants, aircraft structures, and military applications.

The utilization of Nanomaterials is also on the rise, owing to their enhanced mechanical, thermal, and electrical properties. These advanced materials are revolutionizing various industries such as electronics, energy storage, and biomedical devices by offering superior performance and functionality.

Shape Memory Alloys (SMA) are captivating the attention of researchers and engineers alike due to their unique ability to return to their pre-deformed shape upon heating. Coupled with excellent fatigue resistance, SMAs find prominent use in robotics, medical devices, and the automotive industry.

Lastly, Biopolymers are emerging as a sustainable solution in slosh fabrication. These biodegradable and renewable materials contribute to reduced environmental impact. They are finding applications in packaging materials, medical implants, and the textile industry, offering a promising avenue for eco-friendly advancements.

As the slosh fabrication landscape evolves in 2023, the utilization of these materials is reshaping industries and pushing the boundaries of what is possible.

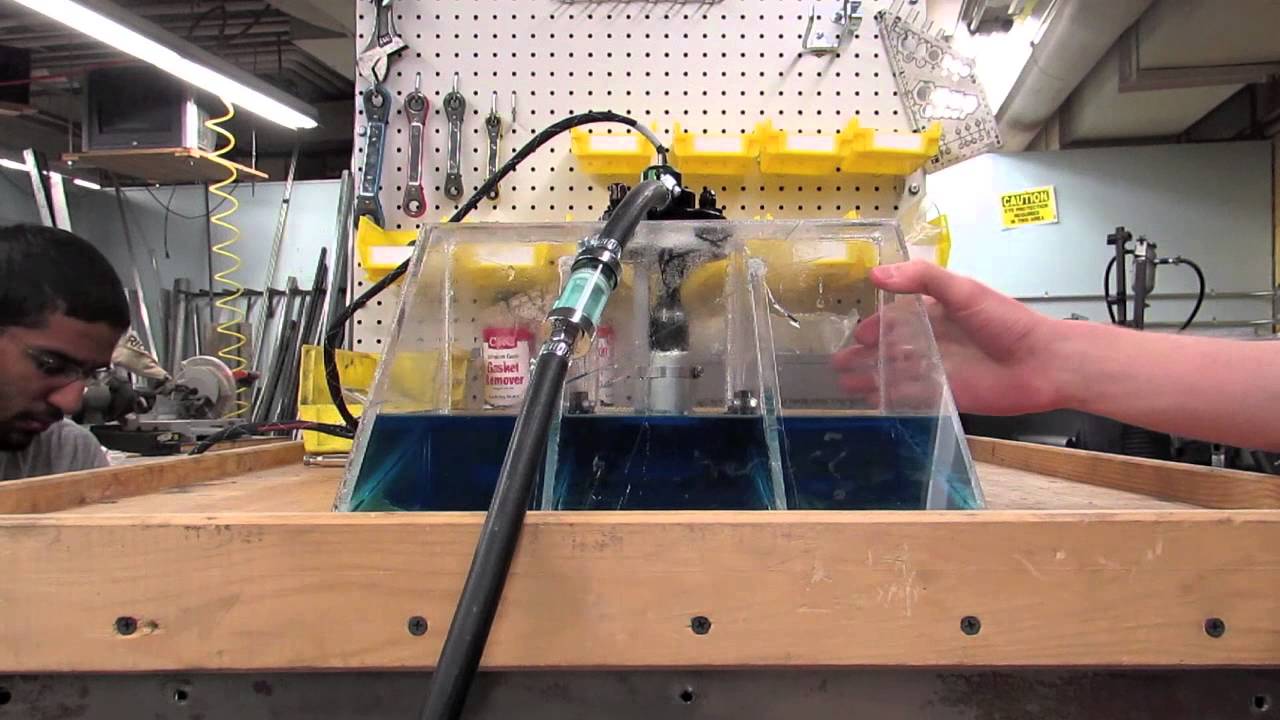

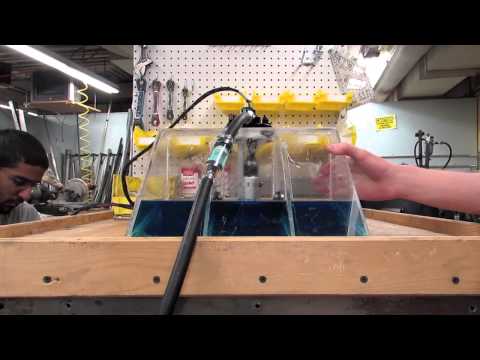

Sloshing Test: Unleashing Fuel Tank Dynamics in KM 2014

Slosh Fabrication: An Overview of the Process

When it comes to manufacturing complex shapes and intricate designs, slosh fabrication is a technique that has gained significant popularity in recent years. This method allows for the creation of unique, three-dimensional objects with a high level of precision and detail. In this article, we will explore the process of slosh fabrication, its applications, and the benefits it offers.

The Process of Slosh Fabrication

Slosh fabrication involves the use of a specialized machine that creates objects through a layer-by-layer deposition process. The material used for fabrication is typically a liquid resin or polymer, which solidifies upon contact with a curing agent. The machine precisely controls the flow of the material, ensuring that each layer is deposited accurately and with the desired level of detail.

One of the key advantages of slosh fabrication is its ability to create objects with internal structures. Unlike traditional fabrication techniques, which can only produce solid objects, slosh fabrication allows for the incorporation of voids, channels, and intricate geometries within the design. This capability opens up a wide range of applications in various industries.

Applications of Slosh Fabrication

The versatility of slosh fabrication has led to its adoption in numerous industries, including healthcare, aerospace, and automotive. Here are some of the key applications of this innovative manufacturing process:

1. Healthcare

Slosh fabrication has revolutionized the field of healthcare by enabling the production of custom medical devices, such as implants, prosthetics, and surgical instruments. The ability to create complex, patient-specific designs allows for better treatment outcomes and improved patient comfort. Additionally, slosh fabrication offers the potential for the development of drug delivery systems with precise dosing and controlled release mechanisms.

2. Aerospace

In the aerospace industry, slosh fabrication has proven invaluable for the production of lightweight yet robust components. The ability to create intricate internal structures enables the development of optimized designs that offer superior strength-to-weight ratios. This is particularly important in the aerospace sector, where weight reduction plays a critical role in improving fuel efficiency and reducing emissions.

3. Automotive

The automotive industry has also embraced slosh fabrication for the production of complex parts, such as engine components, exhaust systems, and interior trim. By utilizing this manufacturing technique, automakers can achieve cost savings, as slosh fabrication eliminates the need for multiple assembly steps and reduces material waste. Moreover, the ability to create intricate designs allows for improved performance and aesthetics.

The Benefits of Slosh Fabrication

Slosh fabrication offers several advantages over traditional manufacturing methods. Here are some of the key benefits:

1. Design Freedom

With slosh fabrication, designers have the freedom to create complex and intricate designs that were previously not possible. The layer-by-layer deposition process allows for the incorporation of internal structures, enabling the production of objects with optimized functionality and performance.

2. Cost Savings

By eliminating the need for multiple assembly steps and reducing material waste, slosh fabrication can lead to significant cost savings in the manufacturing process. Additionally, the ability to produce customized designs on-demand reduces the need for inventory storage, further reducing costs for manufacturers.

3. Improved Efficiency

Slosh fabrication offers improved efficiency by streamlining the production process. The layer-by-layer deposition allows for faster production times, while the ability to create complex designs in a single step eliminates the need for additional machining or assembly processes.

In Conclusion

Slosh fabrication is a versatile and innovative manufacturing process that offers numerous benefits across various industries. Its ability to create complex and intricate designs with internal structures has revolutionized fields such as healthcare, aerospace, and automotive. With its design freedom, cost savings, and improved efficiency, slosh fabrication is likely to continue gaining popularity as a preferred fabrication technique.

Slosh Fabrication

- Slosh fabrication is a technique used in manufacturing industries.

- It involves the manipulation and shaping of liquid materials to create desired products.

- This technique is commonly used in the production of containers, such as bottles and tanks.

- During slosh fabrication, the liquid material is poured into a mold or container and allowed to solidify or cure.

- The process may involve the use of additives or reinforcement materials to enhance the strength and durability of the final product.

- Slosh fabrication can be used with various types of materials, including plastics, metals, and composites.

- It is a cost-effective manufacturing method, as it allows for the production of complex shapes and designs without the need for extensive tooling or machining.

- However, slosh fabrication may have limitations in terms of precision and dimensional accuracy compared to other fabrication techniques.

- Quality control measures, such as proper mixing and curing processes, are essential to ensure the integrity of the fabricated products.

- Overall, slosh fabrication offers a versatile and efficient way to produce a wide range of products in various industries.

Frequently Asked Questions

What is slosh fabrication?

Slosh fabrication is a manufacturing process used to create sloshing tanks, which are containers designed to minimize liquid movement during transportation. It involves the construction of tanks with specialized baffles or partitions that control fluid sloshing, ensuring stability and safety.

How are slosh tanks fabricated?

Slosh tanks are fabricated through a series of steps. First, the design and dimensions of the tank are determined based on the specific application. Then, the tank is constructed using materials such as stainless steel or aluminum. Baffles or partitions are added inside the tank to control fluid movement. Finally, the tank is tested for leaks and structural integrity before being installed.

What are the benefits of slosh fabrication?

Slosh fabrication offers several benefits. It improves the stability of liquid cargo during transportation, reducing the risk of accidents or damage. It also helps to maintain the quality of the liquid by minimizing agitation and preventing contamination. Additionally, slosh tanks can be customized to fit different types of vehicles and applications, making them versatile and adaptable.