Fire Proofing Fabric: Discover the revolutionary fabric that offers unmatched protection against fire hazards. Our fire proofing fabric is specially engineered with state-of-the-art technology, ensuring that you and your loved ones stay safe in any situation. With its innovative design, this fabric goes beyond traditional fire-resistant materials, providing an exceptional level of defense against flames, sparks, and extreme heat. Whether you’re looking to enhance the safety of your home, workplace, or industrial setting, our fire proofing fabric is the ultimate solution. Not only does it provide unparalleled fire resistance, but it also offers remarkable durability and comfort, making it ideal for a wide range of applications.

Say goodbye to worries about accidental fires or potential hazards, as our fire proofing fabric acts as a reliable shield, preventing flames from spreading and reducing the risk of injury or property damage. Its cutting-edge technology ensures that the fabric remains lightweight and breathable, allowing for unrestricted movement and maximum comfort. Engineered to withstand even the most extreme conditions, our fire proofing fabric exceeds industry standards, offering you peace of mind like never before.

Invest in the safety of your surroundings by choosing our exceptional fire proofing fabric. Join countless satisfied customers who have made safety their top priority. Don’t compromise on protection—choose our innovative fabric and experience the ultimate defense against fire hazards.

Fire Proofing Fabric: Ensuring Safety and Protection

Fire accidents can cause devastating consequences, leading to loss of property and, more importantly, endangering lives. One effective way to mitigate such risks is by fireproofing fabrics used in various applications. Fireproofing fabric involves treating it with specialized chemicals to enhance its resistance to flames and heat. In this article, we will explore the importance of fireproofing fabric and the different methods used to achieve it.

1. The Importance of Fireproofing Fabric

Fireproofing fabric is crucial in numerous industries where textiles are extensively used, such as residential, commercial, and industrial settings. In homes, fire-resistant fabrics can provide valuable protection against accidental fires caused by electrical faults, kitchen mishaps, or even open flames. Similarly, fireproofing fabric in public spaces, like hotels and restaurants, can significantly reduce the risk of fire-related accidents and injuries.

Moreover, fireproofing fabric is essential in industrial sectors where flammable substances are present. Flame-resistant fabrics help protect workers from potential hazards, ensuring their safety and well-being. By making fabrics fire-resistant, it becomes possible to contain fires and slow down their spread, buying valuable time for people to evacuate and for emergency responders to control the situation.

2. Fireproofing Methods

There are several methods used to fireproof fabrics, each with its own advantages and applications. The choice of method depends on factors such as the fabric type, desired level of fire resistance, and the intended use of the fabric.

2.1 Chemical Treatments

One common method of fireproofing fabric involves using chemical treatments. These treatments typically involve applying fire-retardant chemicals to the fabric, which react with the fibers to form a protective layer. This layer inhibits the fabric’s ability to ignite and burn rapidly, providing valuable fire resistance.

Chemical treatments can make fabrics fire-resistant without significantly altering their appearance or texture. This makes them ideal for applications where aesthetics are important, such as curtains, upholstery, and clothing. However, it is essential to ensure that the fabric is treated properly and regularly maintained, as the effectiveness of the treatment may diminish over time.

2.2 Laminating and Coating

Another method of fireproofing fabric involves laminating or coating it with fire-resistant materials. Lamination involves bonding a fire-resistant film to the fabric’s surface, creating a protective barrier against flames. Coating, on the other hand, applies a fire-resistant substance to the fabric, which forms a durable layer that enhances fire resistance.

Laminating and coating methods are often used for fabrics that require higher levels of fire resistance, such as those used in industrial settings or for specialized protective clothing. These methods offer excellent protection against flames and heat, but they may alter the fabric’s appearance and texture to some extent.

3. Standards and Certifications

Fireproofing fabric is subject to various standards and certifications to ensure its effectiveness and safety. These standards define the minimum requirements for fire resistance and establish testing methods to evaluate a fabric’s performance.

One widely recognized standard is the National Fire Protection Association (NFPA) 701, which specifies the fire resistance requirements for curtains, drapes, and other decorative fabrics used in public spaces. The UL 94 standard, on the other hand, focuses on materials used in electrical appliances and rates their resistance to ignition and flame spread.

When choosing fireproofed fabrics, it is crucial to look for certifications that validate their compliance with these standards. This ensures that the fabric has undergone rigorous testing and meets the necessary safety requirements.

4. Maintaining Fireproofed Fabrics

While fireproofing fabric enhances its resistance to flames, it is important to remember that no fabric is entirely fireproof. Additionally, fire-resistant properties can diminish over time due to factors such as wear and tear, exposure to sunlight, or improper cleaning.

To maintain the fire resistance of fabrics, regular maintenance and care are essential. It is recommended to follow the manufacturer’s instructions for cleaning and maintenance. Avoid using harsh chemicals or abrasive cleaning methods that may reduce the fabric’s fire resistance. Regular inspections can help identify any damage or deterioration, ensuring that the fabric remains effective in providing fire protection.

5. Conclusion

Fireproofing fabric is a crucial step in ensuring safety and protection in various settings. By making fabrics resistant to flames and heat, the risk of fire-related accidents and injuries can be significantly reduced. With the availability of different fireproofing methods and adherence to relevant standards, fabrics can be effectively protected against fire hazards. Regular maintenance and care are vital to preserving the fire-resistant properties of fabrics. By prioritizing fireproofing fabric, we take a proactive approach towards safeguarding lives and property.

Title: “Ignite Your Interest: Exploring the Power of FR Fabrics”

Demo shortened:

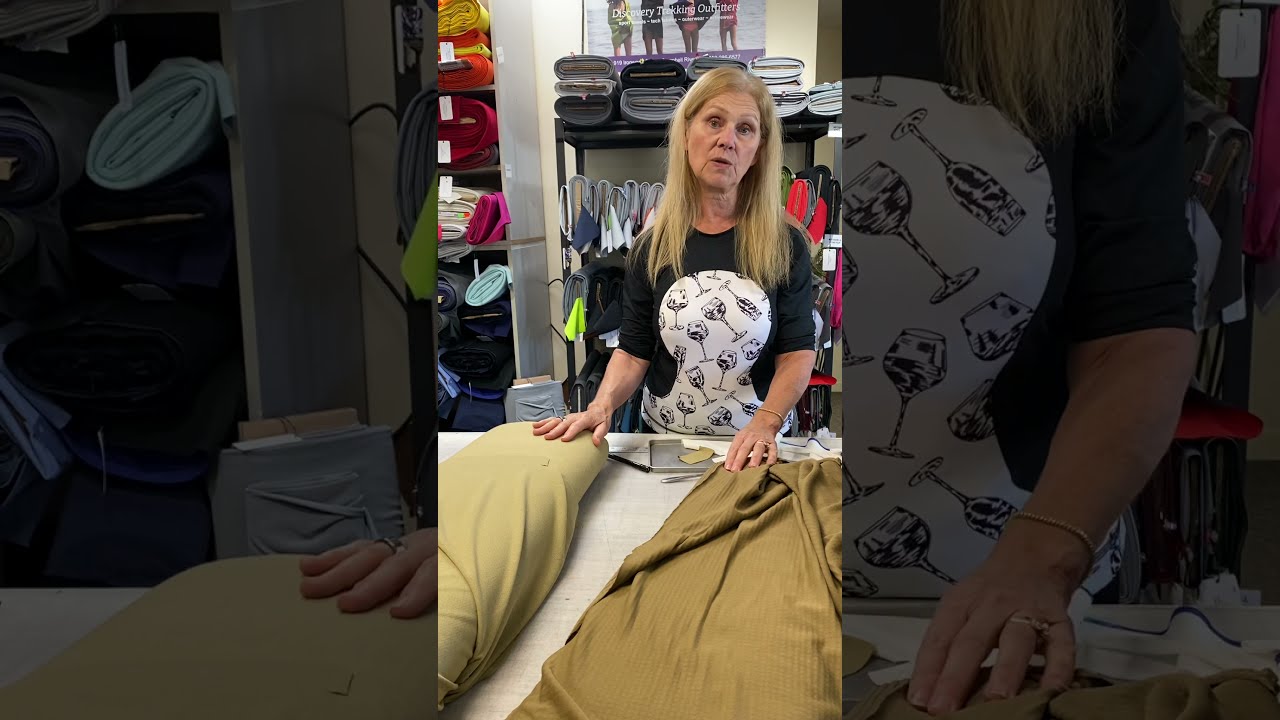

Welcome to our fascinating showcase of FR (flame resistant) fabrics, designed to revolutionize safety in various industries. Witness the extraordinary capabilities of these innovative textiles as we put them to the ultimate test. Let’s dive into a fiery display that will leave you in awe of their unparalleled protection.

Video Source : Discovery Fabrics & Discovery Trekking Outfitters

Fireproofing Fabric

Fire Proofing Fabric

| Material | Fire Resistance Rating | Advantages | Disadvantages |

|---|---|---|---|

| Nomex | UL 94 V-0 | Excellent thermal stability, low smoke emission | Relatively expensive |

| Carbonized Cotton | UL 94 HB | Natural fiber, affordable, good thermal insulation | Less durable, may shrink when exposed to high temperatures |

| Meta-Aramid | UL 94 V-2 | High strength, excellent chemical resistance | Not suitable for high temperatures above 400°C |

| Modacrylic | UL 94 V-0 | Soft and comfortable, inherently flame-resistant | Prone to static electricity buildup |

As fire safety is of paramount importance in various industries, fire proofing fabric plays a critical role in protecting lives and property. This table showcases different materials used in fire proofing fabric, their respective fire resistance ratings, advantages, and disadvantages.

Nomex, renowned for its exceptional thermal stability and low smoke emission, holds a UL 94 V-0 rating. This aramid fiber exhibits remarkable resistance to heat and flame. However, its higher cost may limit its widespread use.

Carbonized cotton, on the other hand, offers a more affordable option with a UL 94 HB rating. This natural fiber provides decent thermal insulation and is widely used in flame-resistant garments. However, it may not be as durable as other options and can shrink when exposed to high temperatures.

Meta-aramid, with a UL 94 V-2 rating, is known for its high strength and excellent chemical resistance. It finds applications in various protective textiles. Nonetheless, it is important to note that meta-aramid may not be suitable for environments with temperatures exceeding 400°C.

Modacrylic fabric, with a UL 94 V-0 rating, offers a soft and comfortable feel while being inherently flame-resistant. It is often used in protective clothing and upholstery. However, it has a tendency to accumulate static electricity.

Understanding the characteristics and trade-offs of different fire proofing fabric materials is crucial for selecting the most appropriate option based on the specific requirements of each application.