Aramid fabric is an extraordinary textile that exudes strength, versatility, and unparalleled durability. Crafted from a unique blend of synthetic fibers, this fabric is celebrated for its exceptional resistance to heat, flames, and abrasions. Its remarkable tensile strength ensures that it can withstand immense pressure and intense environments, making it an ideal choice for a myriad of applications. Whether it’s used in protective gear for firefighters, military personnel, or industrial workers, this fabric offers a level of protection that is second to none.

But what truly sets aramid fabric apart is its lightweight nature, which belies its exceptional strength. This makes it comfortable to wear, allowing individuals to move with ease while still being safeguarded against potential hazards. Additionally, its fire-resistant properties provide an added layer of safety, making it an invaluable asset in high-risk environments.

Furthermore, aramid fabric boasts excellent chemical resistance, ensuring its longevity and reliability in even the harshest conditions. Its ability to withstand extreme temperatures, ranging from freezing cold to scorching heat, makes it an ideal choice for outdoor applications as well.

Whether you require protective clothing, automotive components, or even sporting equipment, aramid fabric offers the perfect blend of strength, flexibility, and durability. With its exceptional properties and wide range of applications, it is undoubtedly a fabric that inspires confidence and trust.

What is Aramid Fabric?

Aramid fabric is a type of textile that is known for its exceptional strength and heat resistance. It is made from a class of synthetic fibers that are derived from aromatic polyamide. Aramid fabrics are widely used in various industries due to their remarkable properties and versatility.

The Properties of Aramid Fabric

Aramid fabric has several key properties that make it highly desirable in many applications. Firstly, it exhibits exceptional strength and is five times stronger than steel on an equal weight basis. This strength makes it ideal for use in applications where durability and toughness are crucial.

Secondly, aramid fabric is highly heat resistant. It can withstand high temperatures without melting or dripping, making it suitable for use in environments where thermal protection is required. Additionally, it has excellent flame resistance and does not support combustion, making it an ideal choice for protective clothing.

Furthermore, aramid fabric has great dimensional stability and does not stretch or shrink significantly under normal conditions. This property ensures that products made from aramid fabric maintain their shape and fit well, even after prolonged use.

Lastly, aramid fabric is highly resistant to abrasion and chemical damage. It can withstand harsh environments and exposure to various chemicals without degradation. This resistance to wear and tear enhances the longevity and performance of products made from aramid fabric.

Applications of Aramid Fabric

Aramid fabric finds numerous applications across various industries due to its exceptional properties. One common use is in ballistic protection, where aramid fabric is used to manufacture bulletproof vests and helmets. Its high strength and resistance to penetration make it an ideal material for personal protective equipment.

In the aerospace industry, aramid fabric is utilized for manufacturing aircraft components, such as wing reinforcement materials and engine parts. Its lightweight yet strong nature makes it suitable for reducing weight while maintaining structural integrity.

In the automotive sector, aramid fabric is used in the production of tires, belts, and hoses. Its high heat resistance and durability ensure these components can withstand extreme conditions and prolonged use.

Moreover, aramid fabric is widely used in the construction industry for reinforcing concrete structures. Its high tensile strength and resistance to chemicals make it an excellent alternative to traditional steel reinforcement.

Additionally, aramid fabric is utilized in the production of protective clothing for firefighters, military personnel, and industrial workers. Its excellent flame resistance and thermal protection properties offer crucial safety benefits in hazardous environments.

Care and Maintenance of Aramid Fabric

Aramid fabric requires proper care and maintenance to ensure its longevity and performance. It is recommended to follow the manufacturer’s instructions for cleaning and washing the fabric. Generally, aramid fabric should be washed in cold water with mild detergent and without using bleach or fabric softeners.

Avoid excessive heat during drying and ironing, as it may damage the fabric’s properties. It is advisable to air dry aramid fabric or use a low heat setting if using a machine dryer. Ironing should be done at a low temperature without steam.

Furthermore, it is crucial to store aramid fabric in a cool and dry place away from direct sunlight and moisture. Proper storage prevents degradation and maintains the fabric’s properties over time.

The Future of Aramid Fabric

Aramid fabric continues to evolve and find new applications across various industries. With ongoing advancements in technology and material science, researchers are exploring ways to enhance its properties further.

Potential future developments include improving the fabric’s resistance to chemicals and UV radiation, increasing its flexibility, and reducing its production costs. These advancements would open up new possibilities for aramid fabric in industries such as electronics, energy, and healthcare.

Overall, aramid fabric remains a remarkable material with exceptional properties that contribute to the advancement and safety of various industries.

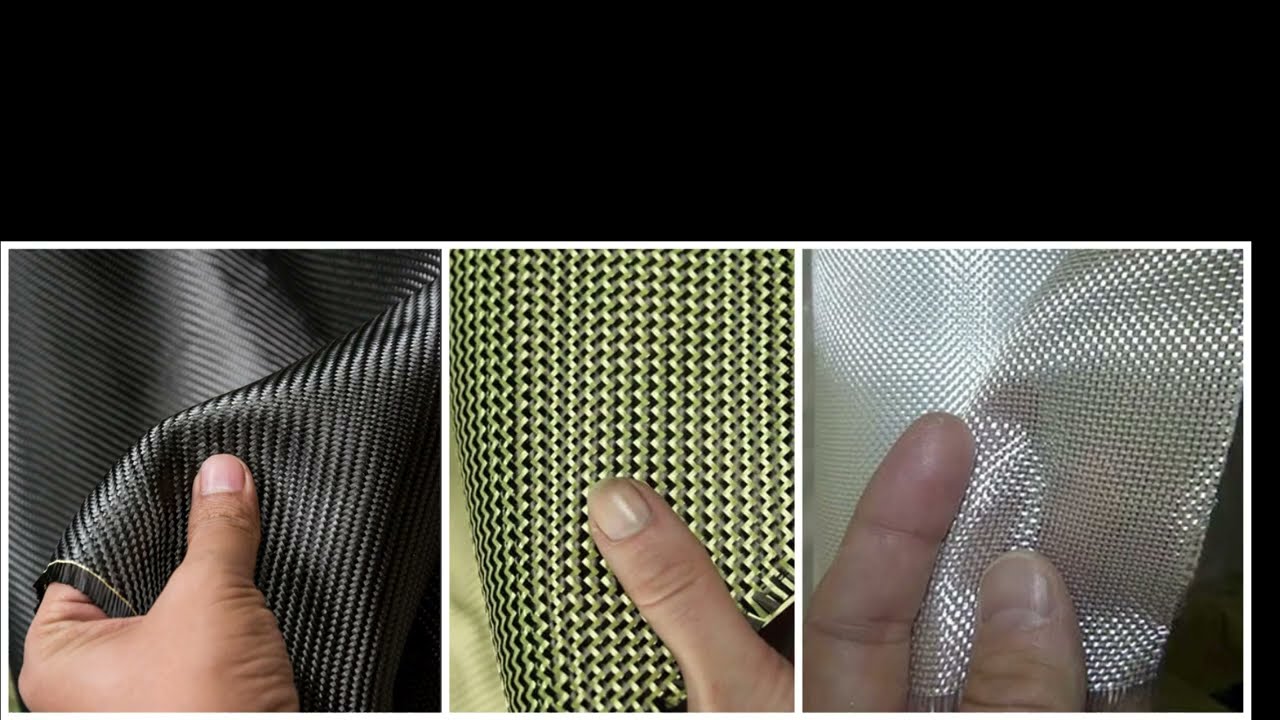

“Unveiling the Power of Carbon, Aramid, and Fiberglass Fibers: A Fascinating Insight”

Video Source : High-temp Textiles

Aramid Fabric

Aramid Fabric

Aramid fabric, also known as aromatic polyamide fabric, is a class of high-performance synthetic fibers that exhibit exceptional strength and heat resistance properties. Widely used in various industries, aramid fabrics have become an indispensable material in applications requiring protection against extreme heat, mechanical stress, and flame.

| Properties | Benefits |

|---|---|

| High Tensile Strength | Aramid fabrics possess remarkable tensile strength, making them ideal for applications requiring robust and durable materials. |

| Excellent Heat Resistance | With a high melting point and exceptional resistance to thermal degradation, aramid fabrics can withstand extreme temperatures without compromising their structural integrity. |

| Flame Retardancy | One of the most notable properties of aramid fabrics is their inherent flame retardancy. They do not support combustion and are self-extinguishing, making them essential for protective clothing and equipment in hazardous environments. |

| Low Weight | Despite their impressive strength, aramid fabrics are lightweight, providing enhanced comfort and flexibility in various applications. |

| Chemical Resistance | Aramid fabrics exhibit excellent resistance to a wide range of chemicals, making them suitable for use in industries where exposure to corrosive substances is common. |

| Electrical Insulation | Due to their non-conductive nature, aramid fabrics find utility in electrical insulation applications, ensuring safety and preventing electrical hazards. |

In conclusion, aramid fabric offers a unique combination of exceptional properties, making it an indispensable material in various industries. Its high tensile strength, excellent heat resistance, flame retardancy, and chemical resistance make it an ideal choice for protective clothing, aerospace components, automotive parts, and many other critical applications.