Filter fabric is a revolutionary textile solution that is designed to enhance the efficiency and effectiveness of filtration systems. With its advanced technology and innovative design, this fabric is engineered to provide exceptional filtration performance, ensuring clean and pure results. The filter fabric is meticulously crafted to capture even the tiniest particles, effectively removing impurities and contaminants from liquids and gases. Its high-quality construction guarantees durability and longevity, making it the ideal choice for a wide range of applications.

This remarkable fabric boasts unparalleled versatility, enabling it to be used in various industries such as water treatment, oil and gas, pharmaceuticals, and many more. Its exceptional filtration capabilities make it an indispensable component in processes that require precision and purity. The filter fabric is also environmentally friendly, as it helps reduce waste and conserve resources by efficiently trapping unwanted particles.

With its impressive performance and reliability, this fabric offers a cost-effective solution that delivers exceptional results. Whether you are seeking to improve the efficiency of your industrial operations or achieve cleaner and healthier environments, the filter fabric is the answer. Experience the power of advanced filtration technology and unlock a world of possibilities with this cutting-edge textile innovation. Trust in the superior quality and effectiveness of filter fabric for all your filtration needs.

2023 Trending Filter Fabric

Filter fabric is a crucial component in various industries, offering superior filtration properties and ensuring the efficient separation of solid particles from liquids or gases. As we look ahead to 2023, let’s explore some interesting information about the latest advancements and trends in filter fabric technology.

| Material | Filtration Efficiency | Applications | Advantages |

|---|---|---|---|

| Nanofiber | Up to 99.9% | Air purification, medical filtration | Unparalleled fine particle capture, high airflow |

| Melt-Blown | Up to 95% | Water filtration, face masks | Cost-effective, excellent liquid and particulate retention |

| Activated Carbon | Varies based on carbon type | Water treatment, air purification | Effective removal of odors, chemicals, and pollutants |

| PTFE Membrane | Up to 99.99% | Chemical processing, pharmaceuticals | Exceptional chemical resistance, high-temperature stability |

One of the most notable trends in filter fabric technology is the rise of nanofiber materials. With their ultrafine fibers and enormous surface area, nanofiber filter fabrics can achieve filtration efficiencies of up to 99.9%. This makes them highly suitable for critical applications such as air purification and medical filtration, where capturing even the tiniest particles is essential.

Another prominent trend is the utilization of melt-blown fabrics for water filtration and face masks. Melt-blown filter fabrics offer a cost-effective solution with their ability to effectively retain both liquid and solid contaminants. They have played a crucial role in combating the spread of airborne diseases and ensuring clean drinking water worldwide.

Activated carbon filter fabrics continue to gain popularity due to their ability to remove odors, chemicals, and pollutants from both air and water. These fabrics are widely used in various applications, such as water treatment and air purification systems, providing efficient and reliable filtration.

Lastly, PTFE (polytetrafluoroethylene) membranes are witnessing increased adoption in industries that require chemical resistance and high-temperature stability. With filtration efficiencies of up to 99.99%, PTFE membranes are ideal for demanding applications like chemical processing and pharmaceutical manufacturing.

2023 promises to be an exciting year for filter fabric technology, with advancements in nanofiber materials, melt-blown fabrics, activated carbon, and PTFE membranes shaping the industry. As we continue to prioritize clean air, pure water, and efficient separation processes, filter fabric innovation will undoubtedly play a pivotal role in achieving these goals.

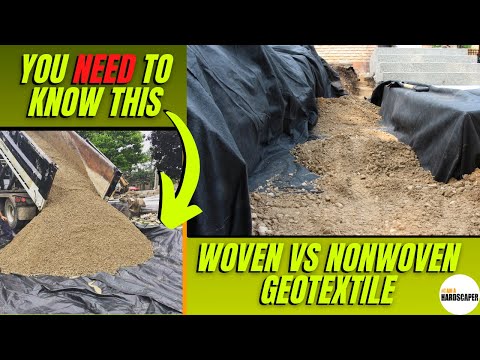

“Decoding Geotextiles: Woven vs Nonwoven Fabrics Unveiled – Picking the Perfect One for Your Project”

What is Filter Fabric?

Filter fabric is a versatile material that is used in various applications to effectively filter out solids while allowing liquids to pass through. Also known as geotextile fabric, it is commonly used in construction, landscaping, and environmental projects. Filter fabric is typically made from synthetic materials such as polyester or polypropylene, and it comes in various forms such as woven, non-woven, or knitted.

The Benefits of Filter Fabric

Filter fabric offers several benefits that make it a popular choice in many industries:

- Durability: Filter fabric is designed to withstand heavy loads and harsh environmental conditions, making it a durable solution for long-term use.

- Separation and Filtration: It effectively separates different materials and filters out solids while allowing water or other liquids to pass through, preventing clogging and promoting efficient drainage.

- Erosion Control: Filter fabric helps prevent soil erosion by stabilizing the soil and promoting proper water drainage, which is crucial in landscaping and construction projects.

- Cost-Effective: By preventing clogging and reducing maintenance requirements, filter fabric can save both time and money in the long run.

- Environmental Protection: Filter fabric helps protect the environment by preventing the contamination of water sources and reducing soil erosion.

Applications of Filter Fabric

Filter fabric has a wide range of applications across various industries:

1. Construction and Civil Engineering

Filter fabric is commonly used in construction projects to provide effective drainage and erosion control. It is often used in retaining walls, roadways, and embankments to prevent soil erosion and stabilize the ground. Additionally, filter fabric is used in drainage systems to filter out sediments and prevent clogging, ensuring the proper functioning of the infrastructure.

2. Landscaping and Gardening

In landscaping and gardening, filter fabric is used to promote proper drainage, prevent weed growth, and protect plants from soil erosion. It is commonly used as a barrier between the soil and gravel or other landscaping materials, ensuring that water can drain freely while preventing the growth of unwanted weeds.

3. Environmental Projects

Filter fabric plays a crucial role in various environmental projects, such as shoreline protection, wetland restoration, and stormwater management. It helps to control erosion, filter pollutants, and protect natural habitats. Filter fabric is also used in sediment control systems to prevent the release of harmful sediments into water bodies.

4. Agriculture

In agriculture, filter fabric is used for crop protection, soil stabilization, and drainage improvement. It helps prevent soil erosion, control weed growth, and ensure optimal water drainage for healthier crops. Filter fabric is also used in greenhouses to provide a suitable environment for plant growth.

5. Industrial Applications

Filter fabric is widely used in various industrial applications, including wastewater treatment, oil and gas filtration, and air filtration. It helps to remove solids, contaminants, and pollutants from liquids and gases, ensuring the cleanliness and safety of industrial processes.

Choosing the Right Filter Fabric

When selecting filter fabric for a specific application, several factors should be considered:

- Material: Choose a fabric material that is suitable for the intended use. Woven fabrics are generally stronger and more durable, while non-woven fabrics provide better filtration capabilities.

- Weight and Thickness: The weight and thickness of the fabric should be selected based on the specific requirements of the project.

- Permeability: Consider the permeability of the fabric to ensure that it allows the desired flow of liquids while effectively filtering out solids.

- UV Resistance: If the fabric will be exposed to sunlight, select a UV-resistant fabric to ensure its longevity.

- Installation and Maintenance: Evaluate the ease of installation and maintenance requirements of the fabric to ensure it is practical for the intended application.

In Conclusion

Filter fabric is a versatile and essential material used in various industries for efficient separation, filtration, erosion control, and environmental protection. Its durability, cost-effectiveness, and numerous applications make it a popular choice for a wide range of projects. By understanding the specific requirements and selecting the right filter fabric, you can ensure optimal performance and long-lasting results.

Filter Fabric

- Helps to prevent soil erosion

- Allows water to pass through while retaining sediment

- Used in construction and landscaping projects

- Can be made from various materials such as polyester or polypropylene

- Available in different thicknesses and strengths

- Can be used for filtration in ponds, pools, and drainage systems

- Provides protection for underlying surfaces against damage

- Easy to install and maintain

- Can be used in combination with other erosion control measures

- Offers long-lasting durability

Frequently Asked Questions

What is filter fabric?

Filter fabric, also known as geotextile fabric, is a special type of fabric that is used in various construction and landscaping projects to prevent the migration of fine particles while allowing water to flow through. It is commonly used in applications such as road construction, drainage systems, and erosion control. The fabric is designed to provide filtration, separation, and reinforcement to improve the overall performance and longevity of the project.

How does filter fabric work?

Filter fabric works by creating a barrier that allows water to pass through while preventing the movement of fine particles. The fabric is made up of closely woven or non-woven fibers that create tiny pores. These pores are small enough to block the passage of fine particles such as silt and clay, but large enough to allow water to flow through. As water passes through the fabric, it carries away any suspended particles, preventing clogging and maintaining the integrity of the project. The fabric also helps to distribute the load across a wider area, reducing the risk of soil erosion and improving the stability of the project.

What are the benefits of using filter fabric?

Using filter fabric offers several benefits in construction and landscaping projects. Firstly, it helps to control erosion by stabilizing the soil and preventing the migration of fine particles. This is especially important in areas prone to heavy rainfall or high water flow. Secondly, filter fabric provides effective filtration, preventing clogging of drainage systems and maintaining their functionality. It also enhances the longevity of the project by reducing the risk of deterioration caused by soil movement or particle migration. Additionally, filter fabric is easy to install and cost-effective, making it a popular choice for various applications.